The manure pellet machine is your ideal choice if you want to produce ideal manure. Next, I will introduce you to 4 different types of organic fertilizer manure pellet machines, and analyze their characteristics and manure granulation process individually.

Types of Manure Pellet Machines (Organic Fertilizer Granulators)

Here's an overview of the different types of granulators commonly used for manure pellet production:

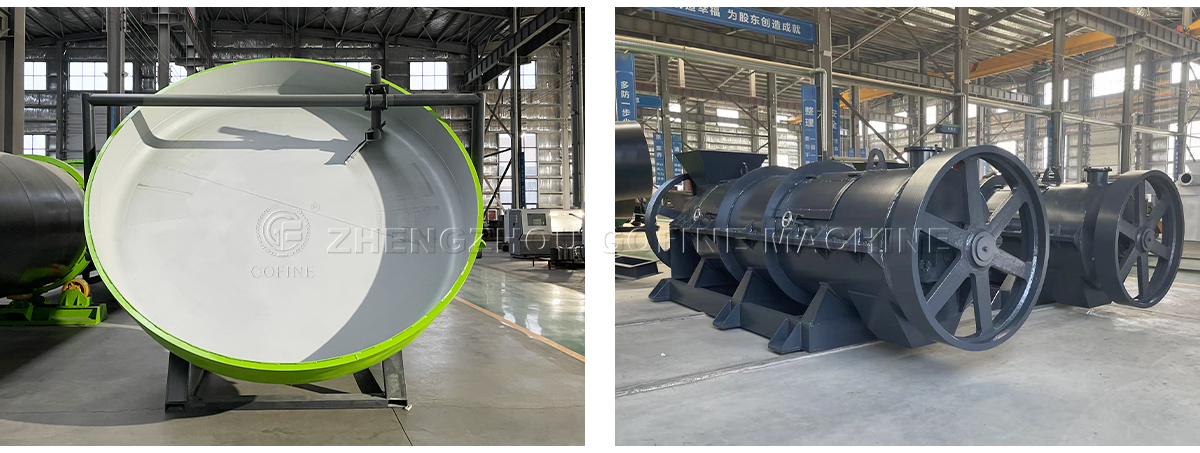

How it Works: A disc granulator, also known as a pan granulator or disc pelletizer, consists of a rotating disc (pan) where manure powder is fed. As the disc rotates, the material agglomerates into pellets due to centrifugal force and the addition of moisture (often sprayed). A scraper helps to prevent material from sticking to the bottom of the disc. The tilt of the disc and the amount of moisture added can be adjusted to control pellet size.

Suitable For: Both organic and compound fertilizer production. Works well with compost, chicken litter, and beef cattle manure.

Advantages: High granulation rate (up to 93%), easy to operate, relatively simple structure, and adaptable to various materials.

Disadvantages: Can be sensitive to material moisture content and particle size. Coarse fibers may require a grinding step beforehand.

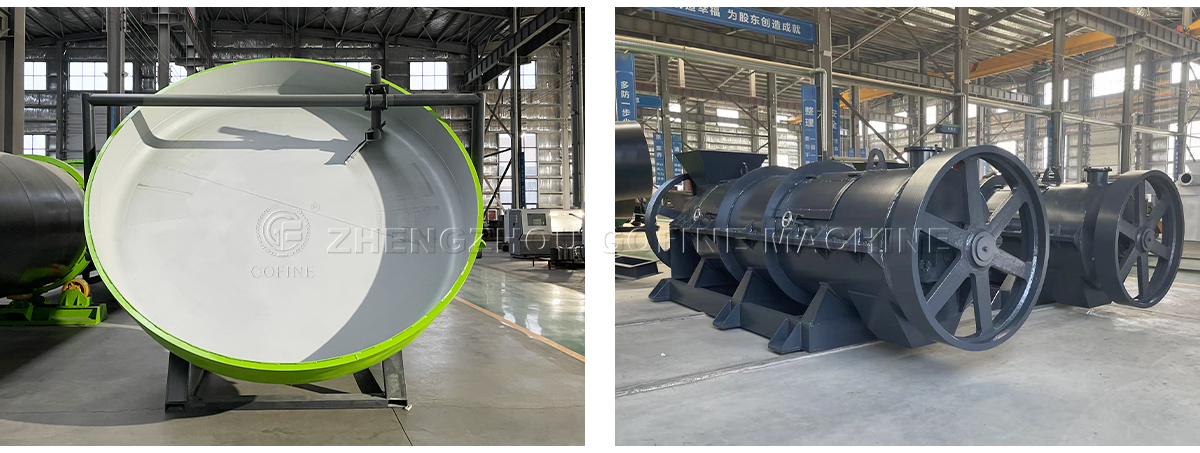

How it Works: This type of granulator uses high-speed rotating stirring teeth inside a horizontal drum to mix, granulate, spheroidize, and compact the manure powder. The stirring teeth create mechanical agitation and aerodynamic forces that cause the material to form into pellets.

Suitable For: Specifically designed for organic fertilizer production, particularly for fine organic materials like chicken manure, composted stalk, and municipal sludge.

Advantages: High granulation rate (over 95%), produces harder pellets compared to disc and drum granulators, and well-suited for direct granulation after fermentation without drying.

Disadvantages: Requires the crushed material to be around 50 mesh for optimal performance.

How it Works: This granulator uses two counter-rotating rollers with matching indentations (molds) to press dry manure powder into pellets. The material is fed between the rollers, and the extrusion force creates dense, uniform granules.

Suitable For: Both compound and organic fertilizer production. [1][8] Works well with powdery dried manure, nitrogen fertilizer, phosphate fertilizer, and other materials.

Advantages: Dry granulation process (no drying required), high granulation rate (over 90%), energy-efficient, and produces pellets with good strength.

Disadvantages: Requires the raw materials to be relatively dry (5%-20% moisture content). The pellets produced are typically elliptical in shape.

How it Works: These machines use a die and roller system to compress manure into pellets. Material is fed onto a flat or ring-shaped die, and rollers press the material through the die openings, forming pellets.

Suitable For: Chicken/cow manure pellets, poultry feed pellets, and all kinds of organic fertilizer pellets.

Advantages: High pelletizing rate and good strength.

Disadvantages: The moisture content should be lower than the required moisture content for the pellet mill.

Choosing the Right Manure Pellet Machine

Selecting the appropriate manure pellet machine depends on several factors, including:

Raw Material: The type and moisture content of the manure you will be using.

Production Capacity: The desired output of your production line.

Pellet Quality: The desired size, shape, and hardness of the pellets.

Budget: The initial investment cost and ongoing operating expenses.

By carefully considering these factors, you can choose the manure pellet machine that best meets your needs and helps you create a valuable organic fertilizer product.

Manure pellet machine organic fertilizer production line

The process of turning manure into fertilizer pellets typically involves several key steps:

1. Collection and Pre-treatment: Raw manure is collected and may undergo pre-treatment steps such as solid-liquid separation and drying to reduce moisture content. Proper ventilation and monitoring are crucial to avoid harmful gas emissions and dust.

2. Composting (Recommended): Composting the manure before pelletizing is highly recommended. This process reduces harmful substances, such as pathogens and weed seeds, and converts nutrients into forms more readily available to plants. Composting also results in a looser, more powdery material that is easier to granulate.

3. Crushing: Crush large pieces of material into powder to facilitate later granulation.

4. Mixing (Optional): Depending on the desired fertilizer composition, other ingredients may be added and mixed with the composted manure.

5. Granulation: This is the core of the process, where the manure is formed into pellets using a granulator. The type of granulator used significantly impacts the characteristics of the final product.

6. Drying (Optional): Depending on the granulation method and desired moisture content, the pellets may be dried to improve their handling and storage properties.

7. Screening (Optional): A screening machine separates the desired particle size, returning unqualified material for further processing.

8. Packaging: The finished manure pellets are then packaged for storage, sale, and application.

If you are interested in our manure pellet machine and organic fertilizer production line, please feel free to contact me!