Product Description

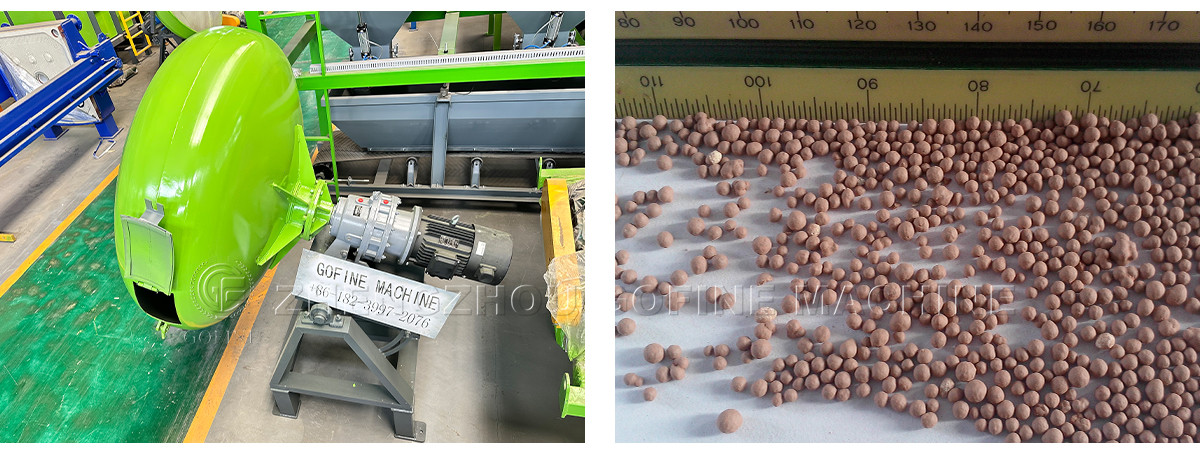

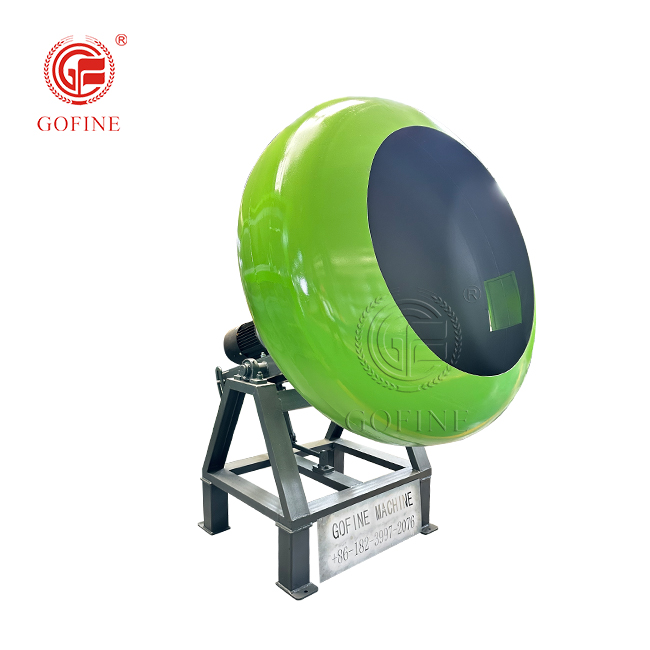

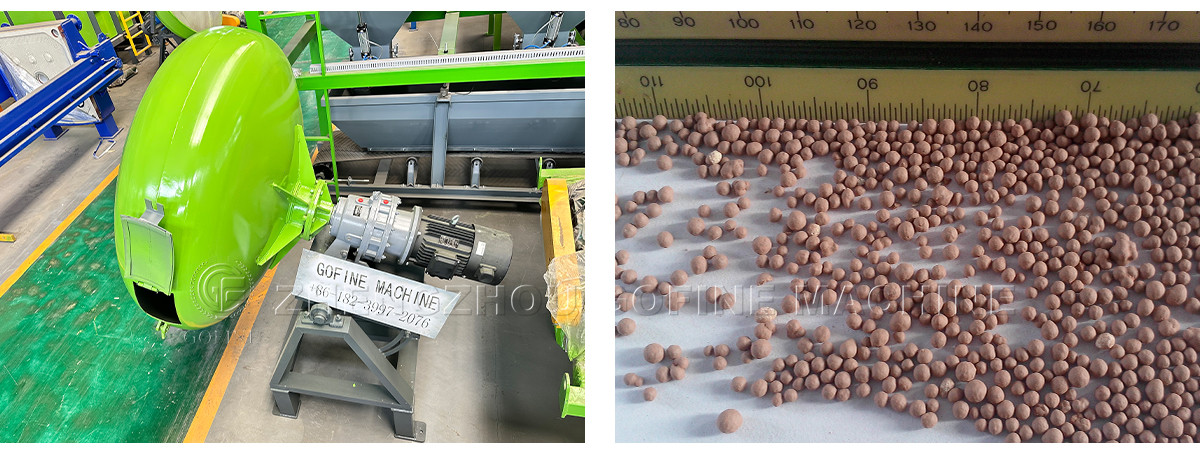

The pan pot type granulator is a high ball forming rate pelletizing equipment with the characteristics of low energy consumption, high output and convenient operation. It is widely used in the granulation of raw materials such as bauxite, shale, clay, sludge, fly ash, slag, phosphate rock powder (or phosphate tailings), phosphogypsum, chicken manure fertilizer, and chemical industry.

Features

1. High balling rate, uniform particle size and high strength of finished balls;

2. Frequency conversion motor is used to adjust the speed according to process requirements;

3. The base of the pelletizer adopts an integrated structure design, stable operation and low noise;

4. Low failure rate, high production efficiency and long service life.

Working Process

The working process of the pot granulator mainly depends on the transmission device. The pot body is rotated through the bridge device, and the axis of the pot body is kept at a certain angle with the horizontal plane. When the powder is added to the pot body from the feed port, water is sprayed inside, and the wet powder gradually forms a ball core during the tumbling process. As the ball cores continue to tumble, rub and collide, their surface gradually increases, and finally the required particles are formed. When the particles reach the predetermined particle size, the finished product is discharged through the discharge door.

Technical Parameters

| Volume (m³) | Production (t/h) | Speed (r/min) | Motor power (kW) |

| 2-25 | 1-20 | 24-12 | 15-150 |

Product Details