Product Description

Our fertilizer coating machine is designed to improve the quality and performance of your fertilizer granules. This machine applies a thin layer of coating material to the surface of fertilizer particles, providing numerous benefits, including preventing caking, controlling nutrient release, and enhancing the overall appearance of the fertilizer. Suitable for both organic and compound fertilizers, our coating machines are a valuable addition to any fertilizer production line.

Features

The coating creates a protective film that isolates fertilizer particles from air and moisture, preventing them from clumping together during storage and transport.

By adjusting the type and thickness of the coating material, you can control the rate at which nutrients are released, ensuring a slow and steady supply for optimal plant growth. Materials such as sulfur, paraffin, resin, and polymers can be used to create this slow-release effect.

The coating process can improve fertilizer efficiency by adding micro-elements, preventing nutrient loss, and improving crop absorption.

Coating can improve the surface smoothness and brightness of fertilizer granules, making them more appealing to customers. Colorants can also be added to create visually distinctive products.

Our machines are built with high-quality, corrosion-resistant materials such as polypropylene lining or acid-resistant stainless steel, ensuring long-lasting performance.

We offer various models and configurations to suit different production needs, with options for liquid or powder coating systems.

Many of our machines feature automated control systems for precise and consistent coating.

Application

Compound Fertilizer Production: Ideal for coating NPK compound fertilizers to improve their handling and nutrient release characteristics.

Organic Fertilizer Production: Suitable for coating organic fertilizer pellets made from materials like cow dung, chicken manure, and pig manure.

Bio-Fertilizer Production: Can be used to add beneficial bacteria to fertilizer granules, protecting them from high temperatures during composting and drying.

Controlled-Release Fertilizer Production: Specifically designed to create slow-release fertilizers with customized nutrient release rates.

Working Process

Material Preparation: Qualified fertilizer granules are transported to the coating machine, ensuring they are dry for optimal coating.

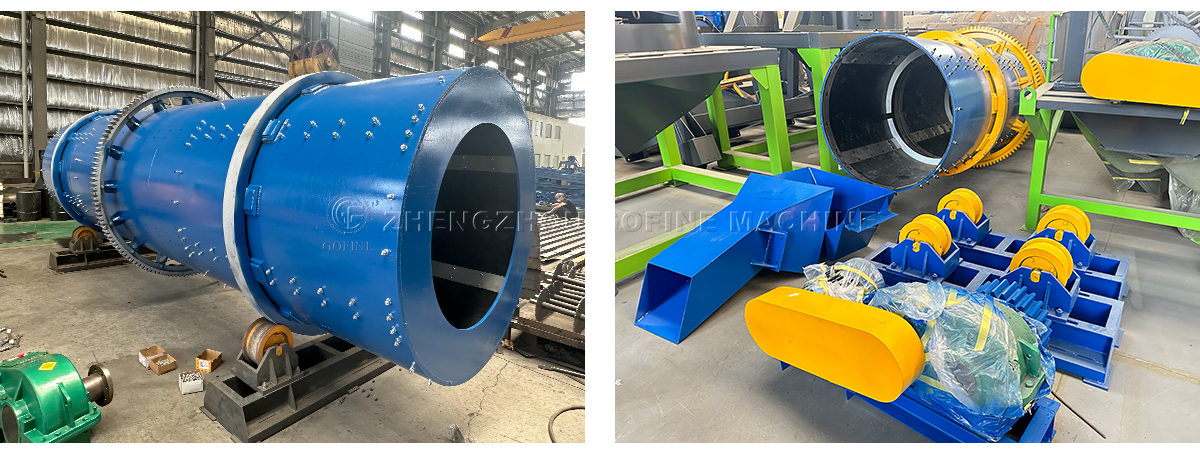

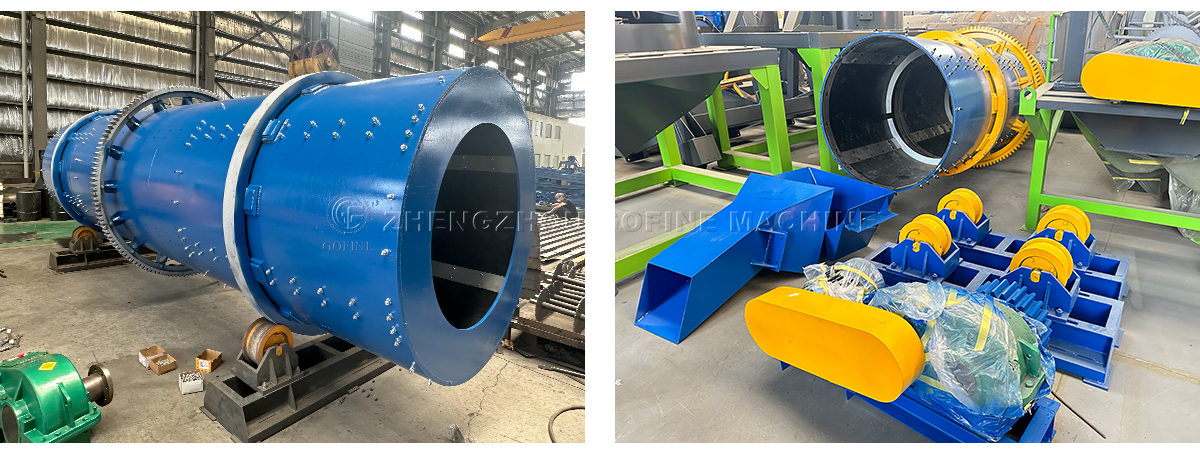

Coating Application: The coating material (liquid or powder) is applied to the fertilizer granules as they move through the rotating drum. Liquid coating agents are sprayed through nozzles, while powder coating agents are fed in using a screw feeder.

Mixing and Coating: Inside the drum, the fertilizer granules are mixed and tumbled, ensuring uniform contact with the coating material. Baffles or strip-shaped shoveling plates inside the drum help to flip and move the particles for even coating.

Drying and Cooling (Optional): Some systems include a drying and cooling stage to solidify the coating and prevent clumping.

Technical Parameters

| Model | Motor power (kw) | Reducer model | Installation tilt angle (°) | Speed (r/min) |

| 1240 | 5.5 | G350 | 2-3 | 11 |

| 1560 | 11 | G400 | 2-3 | 11 |

| 1870 | 18.5 | G500 | 2-3 | 10 |

| 2080 | 22 | G650 | 2-3 | 10 |

Product Details