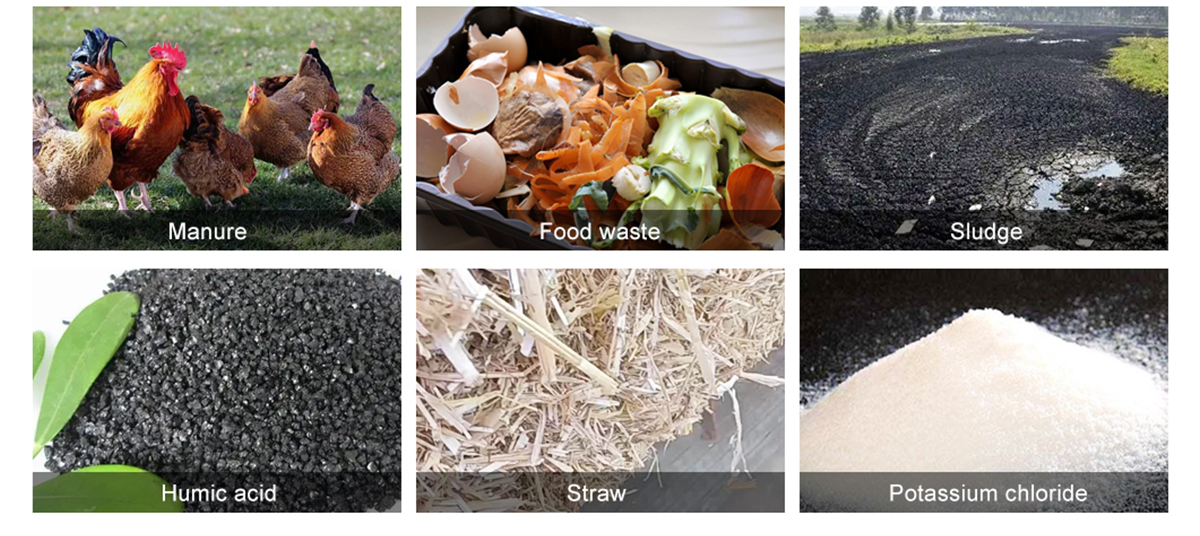

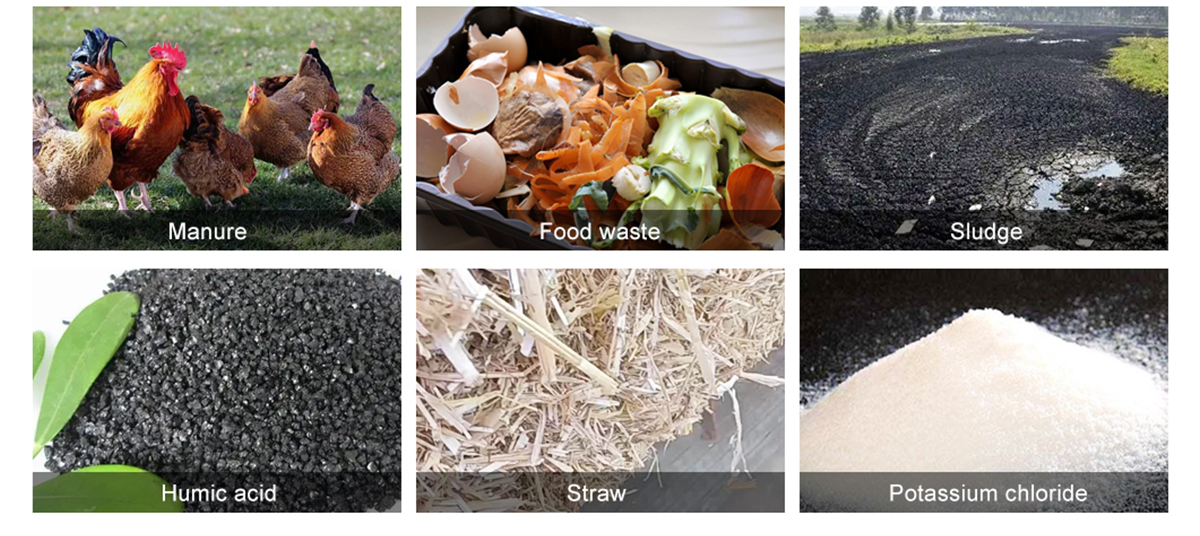

It can be made according to local raw materials, such as municipal solid waste and various crop stalks, leaf weeds, melon vines, rice straw, pine husks, peanut husks, sawdust, chaff powder, bran, fruit residue, dried bagasse, edible Bacteria residues, distiller's grains, beer's grains, sugar residues, vinegar residues, starch residues, cassava residues, citric acid residues, soy sauce residues, monosodium glutamate residues, powder residues, tofu residues, medicine residues, oil residues, oil cakes, bran, cottonseeds Meal, moldy feed, sludge, sugar factory brewery sludge, slaughter scraps, swill (swill) water, leftovers, human and animal manure and other wastes.

Agricultural waste: such as straw, soybean meal, cotton meal, mushroom residue, biogas residue, fungus residue, lignin residue, etc.

Livestock manure: such as chicken manure, cattle, sheep and horse manure, rabbit manure;

Industrial wastes: such as distiller's grains, vinegar grains, cassava residues, sugar residues, furfural residues, etc.;

Domestic waste: such as kitchen waste, etc.;

Municipal sludge: such as river sludge, sewage sludge, etc. ...

The development and utilization of biogas slurry and residue is one of the important contents of biogas promotion.