New Organic Fertilizer Granulating Production Line

There are many raw materials for organic fertilizer, It can be divided into the following categories:

1. Agricultural waste: such as straw, soybean meal, cotton meal, mushroom residue, biogas residue, fungus residue, lignin residue, etc.

2. Livestock and poultry manure: such as chicken manure, cattle, sheep and horse manure, rabbit manure;

3. Industrial wastes: such as distiller's grains, vinegar grains, cassava residues, sugar residues, furfural residues, etc.;

4. Domestic waste: such as kitchen waste, etc.;

5. Urban sludge: such as river sludge, sewage sludge, etc. China's organic fertilizer raw materials classification: mushroom residue, kelp residue, phosphorus citric acid residue, cassava residue, sugar aldehyde residue, amino acid humic acid, oil residue, shell powder, etc., concurrently, peanut shell powder, etc.

6. The development and utilization of biogas slurry and residue is one of the important contents of biogas promotion. According to many years of experiments, the use of biogas slurry and residue has many functions such as fertilizer fields, improving soil, preventing and controlling diseases and insects, and increasing yields.

The main requirements are organic matter content greater than 45%, total nitrogen, phosphorus and potassium nutrients greater than 5%, effective viable bacteria number (cfu), 100 million/g ≥0.2, and powder moisture less than 30%. PH5.5-8.0, the water content of the particles ≤20%.

10000MT/Y, 30000MT/Y, 50000MT/Y, 100000MT/Y, 200000MT/Y

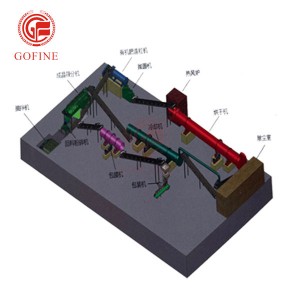

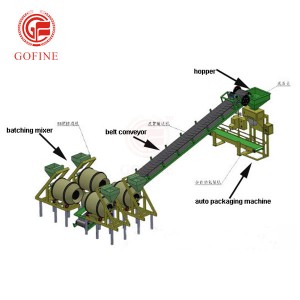

Pin Granulating Production Line for Organic Fertilizer production Diagram:

1. composting and crushing and auto feeding process

1.1. composting or fermentation process for all of various kind s of materials

1.2. organic fertilizer crusher, like chain crusher, Hammer Crusher, etc. In order to get the fine powder materials.

1.3. auto batching scale feeding and weighing system, normally 4 silos or 6 silos or 8 silos, etc. it can feed different raw materials including the trace elements and other ingredients under the required quantity.

1.4. blending or mixing machine to reach 100% full mixing of each materials.

2. Granulation Process

2.1. Pin Granulating machine with capacity less than 8t/h while combined pin and drum granulating machine has capacity more than 8t/h.

2.2. dryer and cooler, to strength the granules quickly.

2.3. screening process to get the suitable and popular marketing granules.

2.4. coating process to beautify the final granules, meanwhile to prevent caking in the warehouse.

3. Packing process

3.1 auto packing machine and semi-auto packing machine is chosen according to different capacity.

3.2 Robot Pallet system is optional.

3.3 Film Winding machine to make clean and tidy packing.

PRODUCTION PICTURE

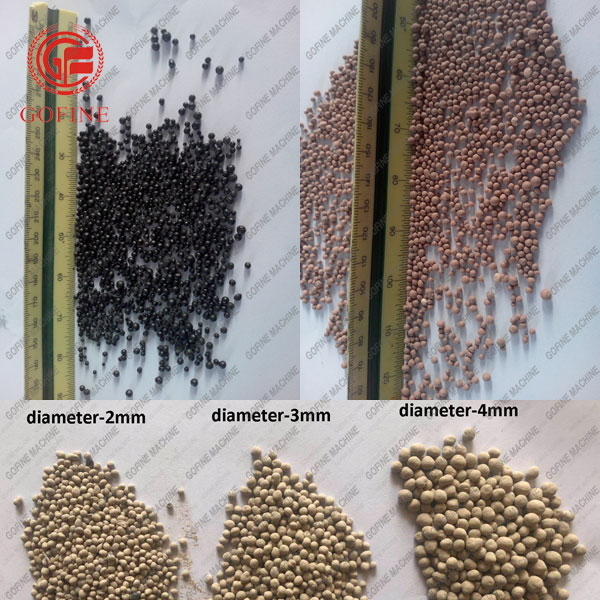

FINAL GRANULES

CARGO DELIVERY

LOOK FORWARD TO YOUR COOPERATION!

SPECIFICATIONS

| Item | Inorganic Compound Granules Fertilizer Production Line | ||||||

| capacity | 3000mt/y | 5000MT/Y | 10000mt/y | 30000mt/y | 50000mt/y | 10000mt/y | 20000mt/y |

| Area suggested | 10x4m | 10x6m | 30x10m | 50x20m | 80x20m | 100x2m | 150x20m |

| Payment terms | T/T | T/T | T/T | T/T | T/T/LC | T/T/LC | T/T/LC |

| Production time | 15 days | 20days | 25 days | 35 days | 45days | 60 days | 90 days |

Overseas Site

Customer’s Visit