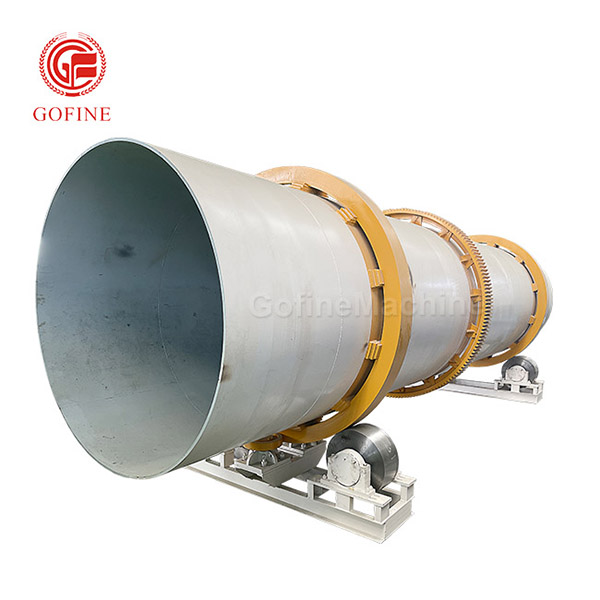

China Manufacturer Ammonium Sulfate Rotary Drum Fertilizer Granulator Machine for Fertilizer Making

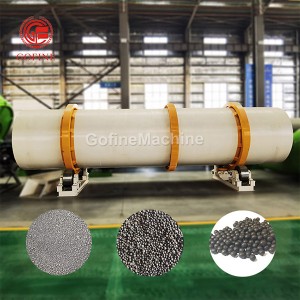

A drum granulator is a molding machine that can make materials into specific shapes. Rotary drum granulator is one of the key equipments in the compound fertilizer industry. It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. The main working method is wet granulation of agglomerates. Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted in the cylinder after being humidified. With the help of the rotating movement of the cylinder, the material particles are formed by extrusion force and agglomerated into balls.

|

Model

|

Power

(kw)

|

Production capacity

(t/h)

|

Weight

(t)

|

Size

(m)

|

|

ZG1.2 x 4

|

5.5

|

1 - 3

|

2.7

|

4.6 x 2.2 x 2.0

|

|

ZG1.4 x 5

|

7.5

|

3 - 5

|

8.5

|

4.8 x 2.8 x 2.3

|

|

ZG1.6 x 6

|

11

|

5 - 8

|

12

|

7.0 x 3.2 x 3.1

|

|

ZG1.8 x 7

|

15

|

8 - 10

|

18

|

8.3 x 3.5 x 3.3

|

|

ZG2.0 x 8

|

18.5

|

10 - 15

|

22

|

9.1 x 3.6 x 3.5

|

|

ZG2.2 x 8

|

22

|

15 - 20

|

28

|

9.5 x 4.4 x 3.9

|

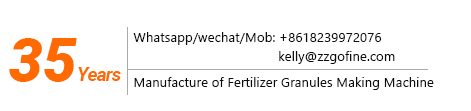

Bracket:The rotating part of the whole body issupported by the bracket,and the force isrelatively large. Therefore, the part of the supporting frame of the machine is weldedby medium carbon steel plate and channel steel.

Roll ring:lt is fixed on both sides of the body tosupport the whole body, and newwear-resistant materials are used toincrease the service life.

Body part:lt is welded with high-quality mediumcarbon steel plate, and has a specialrubber lining plate or plastic liningplate or acid-resistant stainless steellining plate.

Transmission part:The motor drives the pulley, the V-belt andthe reducer to transmit to the main shaft,so that the body works. The transmissionreducer is in the working part of the mainshaft, and the nylon log-off coupling is usedto engage and transmit the drive.

Big gear:lt is fixed on the machine body and mesheswith the transmission pinion to drive themachine body to work in the oppositedirection.