Compound NPK Granules Fertilizer Production line 15-15-15

ammonium sulfate, ammonium nitrate, ammonium chloride, urea, potassium sulfate, potassium chloride, ammonium phosphate and so on.

China National DB15063-94 standard for your information.

National standards stipulate that the effective nutrient content of compound fertilizer (compound fertilizer), the total amount of high-concentration nitrogen, phosphorus and potassium ≥40%, and the content of low-concentration nitrogen, phosphorus and potassium ≥25%, excluding trace elements and medium elements; water-soluble phosphorus content ≥ 40%, water molecule content is less than 5%; particle size is 1~4.75mm, etc.

10000MT/Y, 30000MT/Y, 50000MT/Y, 100000MT/Y, 200000MT/Y

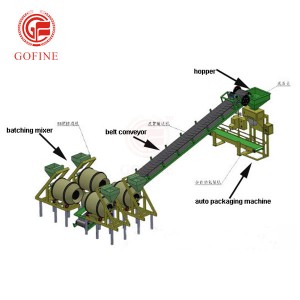

its main equipment is drum granulating machine, drum dryer and cooler and so on. As the following 30000MT/Y production line listed, it starts from Crushing process to final packing process, including the following fertilizer machinery:

1. raw materials crushing and auto feeding process

1.1. compound fertilizer crusher, like urea crusher, MOP crusher, Cage Crusher, Hammer Crusher, etc. In order to get the fine powder materials.

1.2. auto batching scale feeding and weighing system, normally 4 silos or 6 silos or 8 silos, etc. it can feed different raw materials including the trace elements and other ingredients under the required quantity.

1.3. blending or mixing machine to reach 100% full mixing of each materials.

2. Granulation Process

2.1. drum Granulating machine, equipped with other accessories like boiler, to make the powder into granules.

2.2. dryer and cooler, to strength the granules quickly.

2.3. screening process to get the suitable and popular marketing granules.

2.4. coating process to beautify the final granules, meanwhile to prevent caking in the warehouse.

3. Packing process

3.1 auto packing machine and semi-auto packing machine is chosen according to different capacity.

3.2 Robot Pallet system is optional.

3.3 Film Winding machine to make clean and tidy packing.

MACHINE PICTURES IN DETAILS

LOOK FORWARD TO YOUR COOPERATION!

| Item | Inorganic Compound Granules Fertilizer Production Line | ||||

| capacity | 10000mt/y | 30000mt/y | 50000mt/y | 100000mt/y | 200000mt/y |

| Area suggested | 30x10m | 50x20m | 80x20m | 100x20m | 150x20m |

| Payment terms | T/T | T/T | T/T/LC | T/T/LC | T/T/LC |

| Production time | 25 days | 35 days | 45days | 60 days | 90 days |

YOU CAN CONTACT US BY EMAIL OR WHATSAPP FREELY FOR MORE INFORMATION. Overseas working site  Customers Visit

Customers Visit