As global agriculture continues to grow and change, so does the demand for fertilizers. According to research, the global fertilizer market is expected to reach nearly $500 billion by 2025. As the global population increases and concerns about food security increase, the modernization and efficiency of agricultural production require more fertilizer support.

Types and differences of fertilizers

Organic fertilizer

Organic fertilizer is usually made by fermentation of animal manure, plants, waste, straw, etc. Contains rich organic matter, effectively improves soil structure, and releases fertilizer effect slowly.

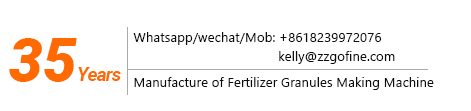

Compound fertilizer

Chemical fertilizer is mainly composed of nitrogen, phosphorus, and potassium, and the proportion can be adjusted according to different needs. The fertilizer effect is fast and can meet the nutrient needs of different plants at each growth stage.

The selection of raw materials in fertilizer production directly determines the characteristics and content of the fertilizer, which is related to the fertilization effect and crop growth.

Fertilizer Production Process

Organic fertilizer production process

The production process of organic fertilizer mainly includes raw material collection, crushing pretreatment, fermentation, composting, and packaging.

In the production process of organic fertilizer, the fermentation link is particularly important. Suitable fermentation equipment can double your work efficiency!

1. Diesel compost turner: a drivable compost turner with flexible movement and unlimited space.

2. Trough-type pile turner: The equipment needs to be placed in a specific trough, and the materials are stacked in the trough to achieve uninterrupted turning.

3. Roulette compost turner: It has the characteristics of fast turning speed and convenient operation, and is suitable for large-scale compost production sites.

4. Fermentation tank: It adopts a high-temperature fermentation method and completes harmless treatment in 10 hours. It is suitable for large-volume and efficient fermentation production.

Compound fertilizer production process

Compound fertilizer is composed of a variety of major nutrients (nitrogen, phosphorus, potassium) and some trace elements. Compared with organic fertilizer production, compound fertilizer is more complicated.

1. Raw material ratio: Prepare the corresponding ratio according to the fertilizer formula not used.

2. Crush and mixer: Crush the raw materials to the ideal particle size and stir thoroughly according to different fertilizer formulas.

3. Granulator: Materials are processed into particles of uniform size through different types of granulators.

4. Drying and drying: Carry out necessary drying and cooling according to the condition of the processed particles.

5. Screening and packaging: The finished particles are screened to improve the quality of the particles, and unsatisfactory particles are crushed and re-granulated. Finally, it is transported to the automatic weighing and packaging machine for packaging processing.

The application of fertilizers has a vital impact on improving crop yields, soil fertility, plant growth, and resistance to pests and diseases. In the future, fertilizer production will also tend to be more sustainable in development directions such as green environmental protection and resource reuse. Gofine machine is committed to providing more feasible solutions to agriculture and contributing to the new era of fertilizer production.

Post time: Dec-01-2023