Transforming Cost into Profit with Value-Added Fertilizer Pellets

For farm managers and agri-business investors, managing manure is often viewed as a necessary cost. However, with the right technology, this perspective can shift dramatically. Investing in an animal manure pellet machine and its supporting organic fertilizer production line is not merely an equipment purchase; it is a strategic business decision to create a new revenue stream, reduce environmental liabilities, and enhance sustainability credentials. This article builds the business case, focusing on the Return on Investment (ROI) and the market advantages unlocked by producing standardized fertilizer pellets.

The Financial Drivers: From Disposal Cost to Product Revenue

The economic rationale rests on converting a cost center into a profit center.

Eliminating Disposal and Storage Costs

Raw manure handling involves significant costs: labor for spreading, potential fees for off-site disposal, and the environmental risk of runoff. By processing manure on-site with a compost machine and pellet machine, these recurring costs are drastically reduced or eliminated.

Creating a Marketable Commodity

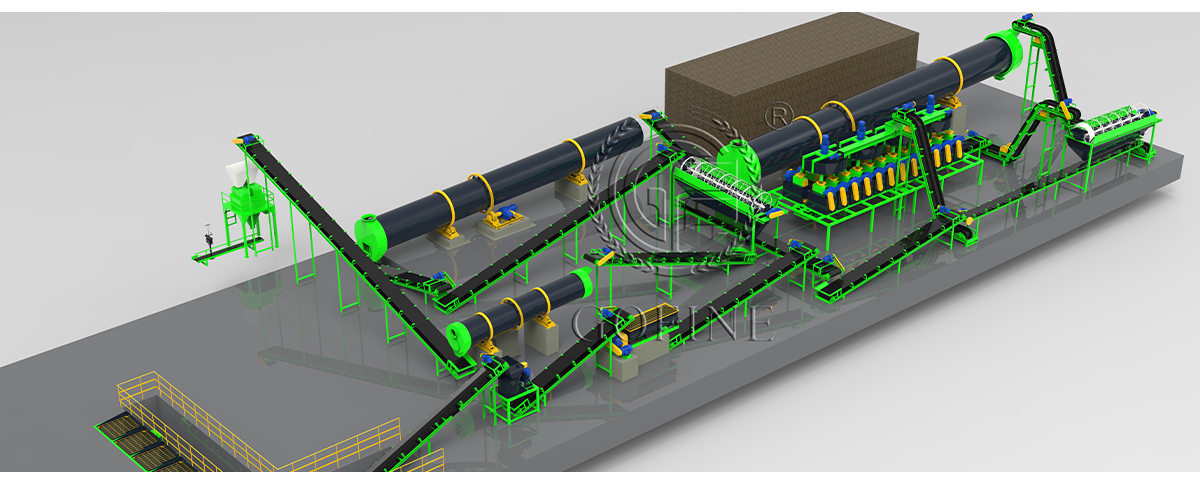

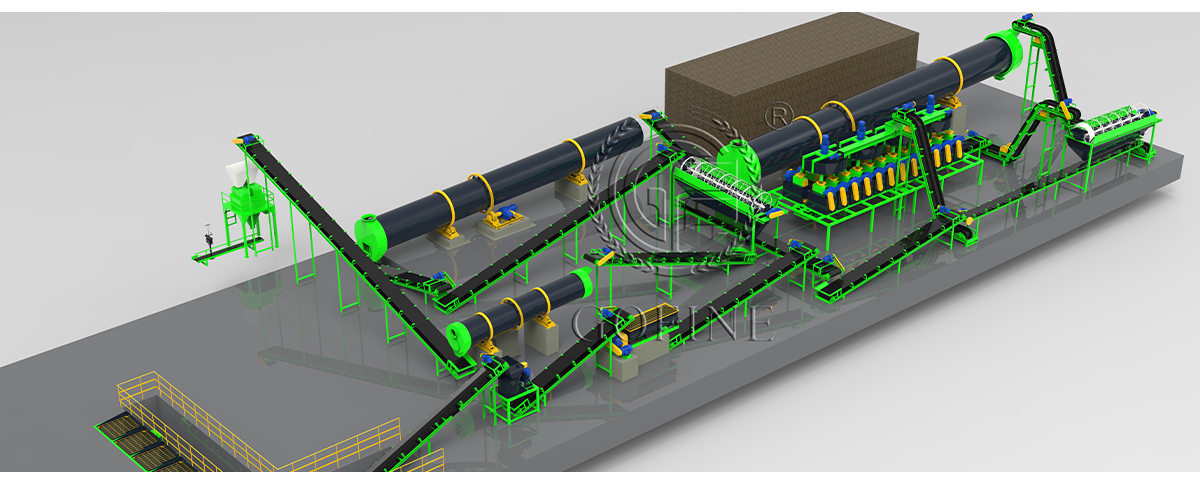

The core value addition lies in the pelletization process. Bulk, odorous compost has a limited market and low price per ton. When processed into uniform, dry, dust-free fertilizer granules via a rotary drum churning granulator or pellet mill, the product undergoes a transformation.

Increased Value: Pelleted organic fertilizer can sell for 2 to 5 times the price of bulk compost, depending on quality and certification.

Market Expansion: Pellets are easy to bag, ship over long distances, and sell into retail garden centers, horticultural suppliers, and export markets—channels inaccessible to loose compost.

Brand Potential: A consistent, pelletized product allows for brand development, packaging, and premium positioning, particularly for bio organic fertilizer blends.

Calculating the Investment and Payback Period

A realistic ROI analysis for a manure pellet machine operation must consider both costs and benefits.

Key Cost Factors (Capital & Operational)

Capital Expenditure (CapEx): The total cost of the production line, including the pelletizer (fertilizer pellet machine), compost machine, mixer, dryer, cooler, screener, and bagging equipment.

Operational Expenditure (OpEx): Labor, energy (for running machines and drying), maintenance, packaging materials, and marketing.

Key Revenue Factors

Annual Pellet Production Volume: Based on your raw manure availability and line capacity.

Selling Price per Ton: Determined by your local/regional market for premium organic pellets.

Value of Avoided Costs: The annual savings from not having to manage/dispose of raw manure traditionally.

The ROI Equation

A simplified model: Payback Period (Years) = Total CapEx / (Annual Pellet Revenue + Annual Avoided Costs - Annual OpEx). For a mid-scale cow dung fertilizer production line, payback periods often range from 2 to 4 years, after which the operation generates pure profit.

Strategic Advantages Beyond Direct Revenue

The benefits of integrating a fertilizer granulation system extend beyond the balance sheet.

Environmental Compliance and CSR: Demonstrates proactive nutrient management, reduces runoff risk, and enhances the farm's corporate social responsibility profile.

Operational Efficiency: Pelletizing condenses product volume, slashing storage and transportation requirements by up to 70% compared to loose compost.

Diversification and Risk Management: Creates a new, resilient income stream that is less susceptible to volatility in traditional commodity markets.

Making the Decision: Is a Pellet Line Right for You?

The investment is most compelling for operations with:

A large, consistent supply of manure (e.g., dairy, poultry, or beef operations with 500+ head).

Access to markets willing to pay a premium for quality organic inputs.

The long-term vision to integrate vertically and capture more value from their production cycle.

In conclusion, a manure pellet machine is the engine of a circular economy business model on the farm. By performing a detailed analysis of your costs, potential revenue, and strategic goals, you can confidently determine if this powerful technology is the key to unlocking the latent value in your organic waste, turning the challenge of manure management into a cornerstone of your profitability.