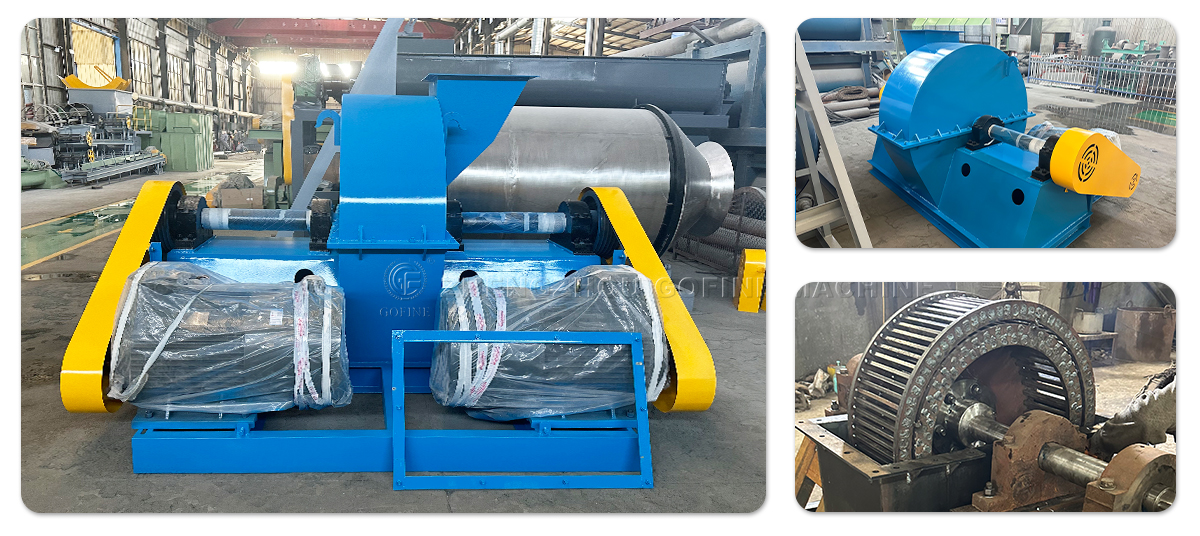

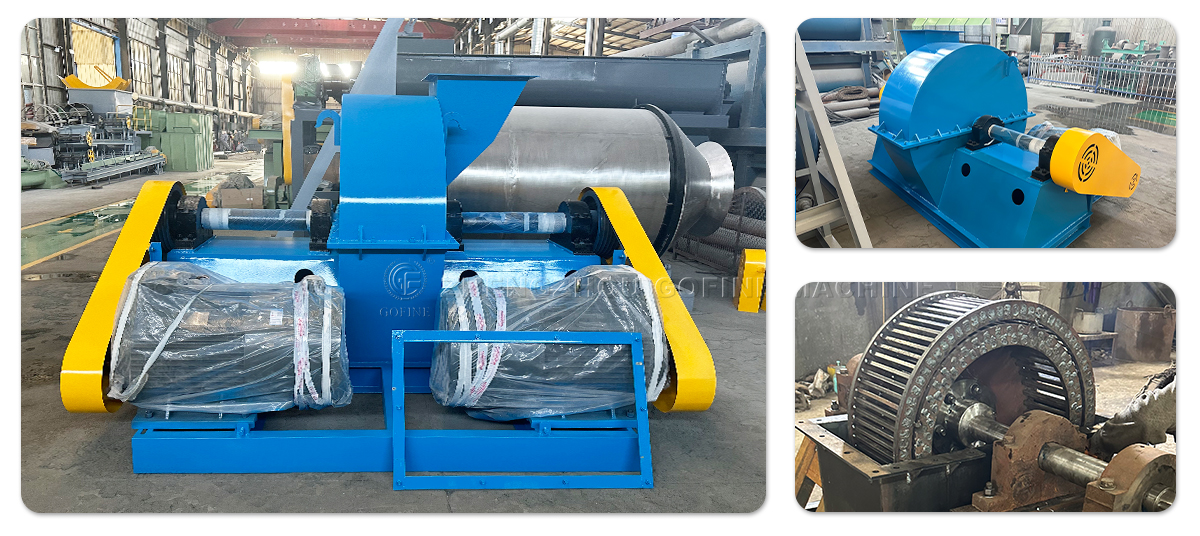

Product Overview

The High-performance Carbon Steel Dual Electric Engine Animal Manure Compost Grinder is a heavy-duty grinding device tailored for pre-processing animal manure and mature compost in organic fertilizer production. Its dual-electric-engine design (15 kW + 11 kW) delivers strong torque to break down clumpy manure (e.g., cow, chicken, pig manure) and semi-decomposed compost into fine particles (≤3 mm), solving the problem of uneven material mixing in subsequent granulation steps. Made of Q235 high-carbon steel (surface quenched to HRC 45), it withstands abrasion from fibrous manure components (e.g., straw in chicken manure) and supports continuous operation in harsh workshop environments. It is especially suitable for small to medium organic fertilizer plants that process fresh manure with high moisture content.

Product Features

Dual-Engine Power System: Two synchronized motors provide combined torque of 850 N·m, enabling efficient grinding of clumpy manure (up to 300 mm in diameter) with a processing capacity of 2-6 tons per hour.

Uniform Particle Size: The multi-layered blade system (12 movable blades + 8 fixed blades) ensures ≥95% of output particles are ≤3 mm, meeting the raw material requirement for organic fertilizer granulation.

Moisture Adaptability: Handles raw materials with 40-70% moisture content (common for fresh manure), thanks to the anti-clogging feed hopper (equipped with a vibrating device to prevent material bridging).

Durable Structure: High-carbon steel body (thickness 12 mm) and wear-resistant blade material (SKD11 alloy steel) reduce blade replacement frequency—blades last 1500 working hours for chicken manure, 2000 hours for cow manure.

Low Noise Operation: Equipped with a sound insulation cover and shock-absorbing rubber pads, the operating noise is ≤82 dB (measured 1m from the machine), complying with industrial workplace noise standards.

Applications

Pre-processing of fresh animal manure: Grinds cow/pig manure (mixed with straw) into fine material for aerobic fermentation, accelerating microbial decomposition.

Refining mature compost: Breaks down large compost clumps (formed during fermentation) into uniform particles, ensuring smooth feeding into granulators.

Soil improvement material production: Grinds decomposed garden waste (e.g., leaf compost) into fine powder for blending with organic fertilizer to enhance soil structure.

Small-scale biogas plant residue processing: Crushes biogas residue (high moisture, fibrous) into usable material for organic fertilizer, realizing waste recycling.

FAQ

Q: Can it grind manure with foreign objects (e.g., stones, wire)?

A: The machine is equipped with a magnetic separator at the feed inlet to remove metal fragments; however, stones ≥50 mm may damage blades—we recommend installing a pre-screening conveyor (optional) to filter large impurities.

Q: How to adjust the grinding gap for different materials?

A: The gap between movable and fixed blades can be adjusted via the side adjustment bolts (range: 0.5-5 mm). For fresh manure, set the gap to 2-3 mm; for dry compost, set to 0.5-1 mm for finer particles.

Q: Does it require a fixed installation?

A: Two installation options are available: fixed (anchored to the ground) for long-term workshop use, or mobile (mounted on a trailer with wheels) for on-site manure processing (e.g., at livestock farms).

Q: What is the power consumption per ton of material?

A: Average power consumption is 8-12 kWh/ton, depending on material moisture—lower moisture (40-50%) consumes 8 kWh/ton, higher moisture (60-70%) consumes 12 kWh/ton.