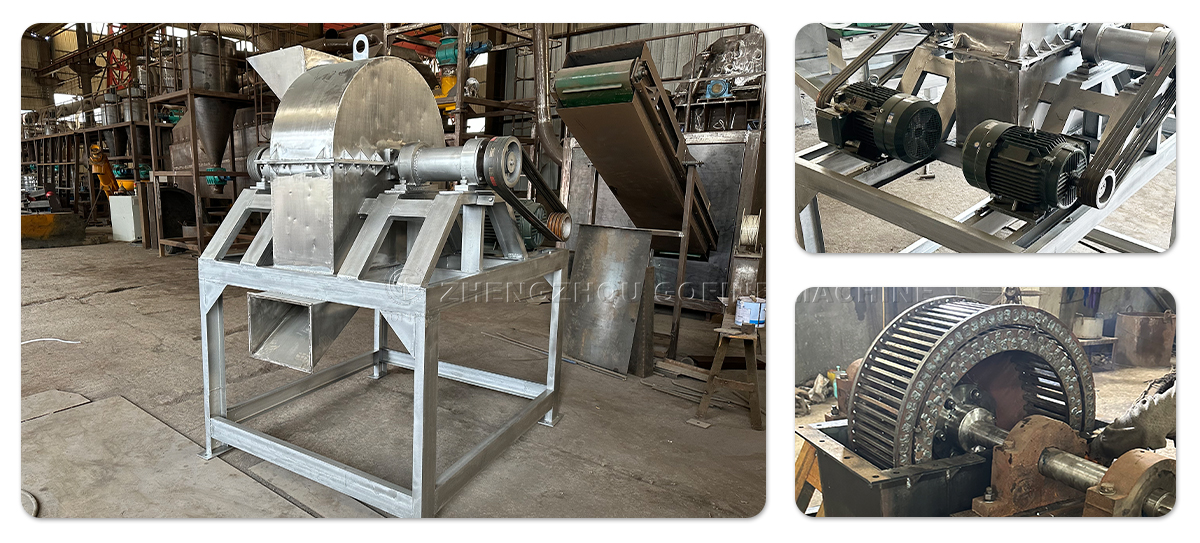

Product Overview

The Chemical Mineral Powder Stainless Steel Cage Pulverizer is a specialized fine-grinding equipment designed for the fertilizer industry’s mineral processing needs. Crafted with food-grade 304 stainless steel (resistant to corrosion from acidic/alkaline minerals), it adopts a high-speed rotating cage structure to crush hard mineral raw materials—such as phosphate rock, potassium chloride, and bentonite—into uniform fine powder (80-325 mesh) without secondary contamination. Unlike traditional hammer mills, its enclosed cage design minimizes dust emission and ensures consistent particle size, making it a core device for producing high-purity mineral additives in compound fertilizer production lines. It supports continuous operation with a stable processing capacity, ideal for medium to large fertilizer plants requiring precise mineral powder preparation.

Product Features

Corrosion-Resistant Construction: Full 304 stainless steel body and internal components (cage bars, screen) resist chemical erosion from mineral salts (e.g., ammonium nitrate), extending service life by 300% compared to carbon steel pulverizers.

Adjustable Fineness Control: Equipped with replaceable stainless steel screens (80-325 mesh) to achieve customized powder fineness—80 mesh for basic mineral blending, 325 mesh for high-end micro-element fertilizer production.

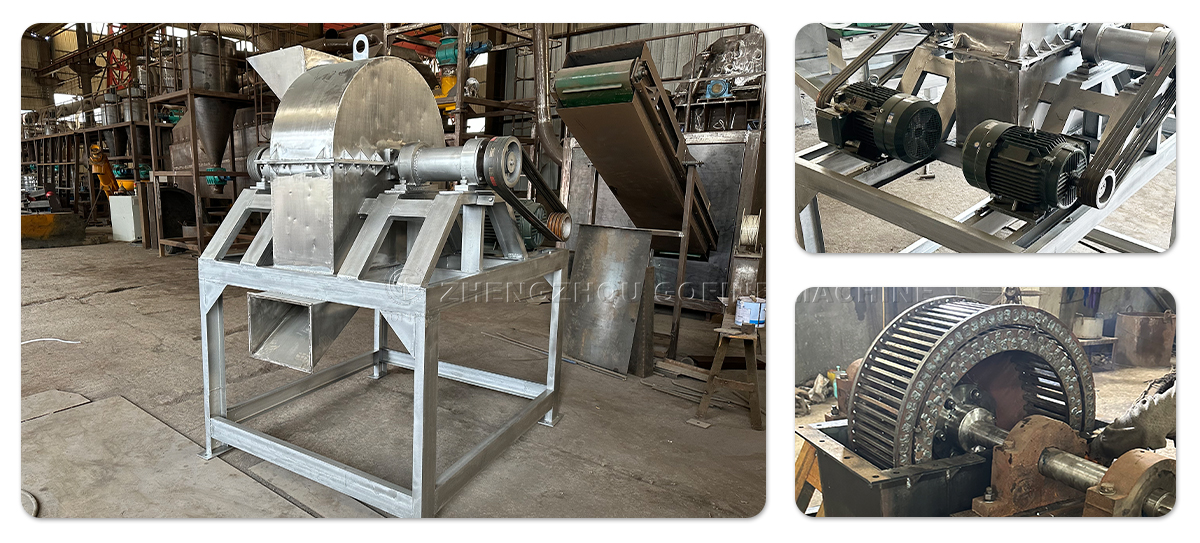

High Grinding Efficiency: The cage rotor operates at 1800-2200 rpm, driven by a 11-37 kW variable-frequency motor, enabling a processing capacity of 1-5 tons per hour (depending on mineral hardness).

Dust-Free Operation: Sealed grinding chamber with a built-in pulse dust collector achieves ≤5 mg/m³ dust concentration, complying with EU CE and US OSHA air quality standards.

Overload Protection: Intelligent torque monitoring system automatically reduces speed or stops the machine if hard impurities (e.g., metal fragments) enter, preventing damage to internal parts.

Applications

Fine grinding of mineral raw materials for compound fertilizers, such as phosphate rock powder (for phosphorus nutrients) and potassium salt powder (for potassium nutrients).

Processing of micro-element additives (e.g., zinc sulfate, borax) into ultra-fine powder to ensure uniform mixing with base fertilizers.

Production of organic-inorganic compound fertilizers requiring high-purity mineral components (e.g., medical waste-derived organic fertilizers with mineral supplements).

Laboratory-scale mineral powder preparation for fertilizer formula R&D, with adjustable fineness to test nutrient release efficiency.

Working Process of Stainless Steel Cage Pulverizer

The stainless steel cage crushing equipment forms a strong impact force through the high-speed rotation of the inner and outer cage bars, so that the material is quickly crushed during the rotation process. The material is subjected to multiple impacts and shearing inside the equipment to ensure the uniformity and fineness of the crushing.

Technical Parameters of Cage Pulverizer

| Model | Feed port size (mm) | Power (kW) | Production capacity (t/h) | Overall dimensions (mm) |

| GFLSJ-600 | 380*320 | 11*2 | 4-6 | 1500*1500*1500 |

| GFLSJ-800 | 380*250 | 15*2 | 6-10 | 1500*1400*1500 |

In addition to stainless steel cage pulverizer, we also offer a variety of models of carbon steel and dust-free cage crushers to meet your needs in crushing efficiency, material requirements and hygiene standards.