Product Overview

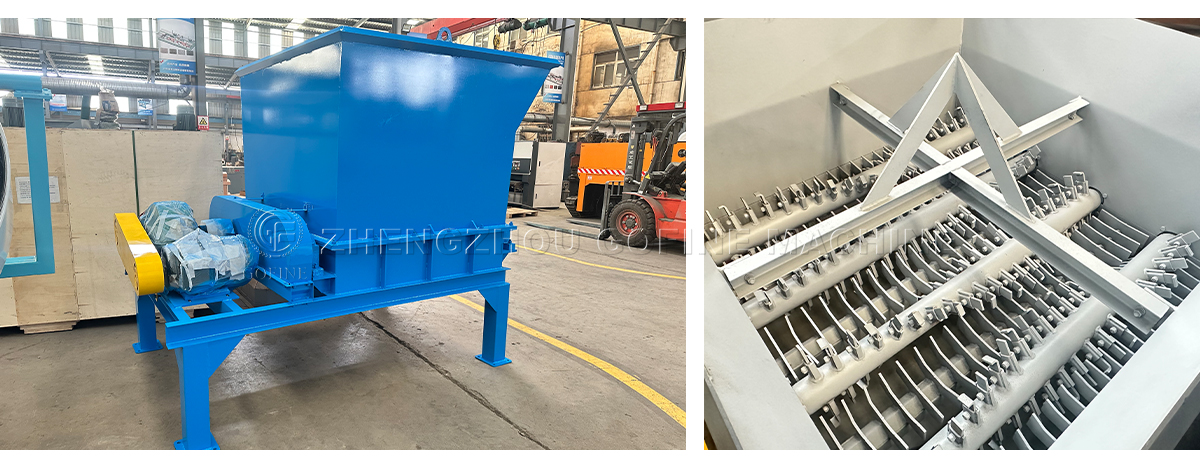

The Ton Bag Breaker & Crusher is a state-of-the-art, integrated system engineered to streamline the processing of bulk materials delivered in Flexible Intermediate Bulk Containers (FIBCs), commonly known as ton bags or jumbo bags. This robust machine seamlessly combines powerful bag breaking and high-speed crushing into a single, efficient unit. It is specifically designed to handle the challenges of caked, solidified, and lumpy materials, transforming them into a consistent, free-flowing product ready for the next stage of your production line. The Ton Bag is the cornerstone of modern bulk material handling, ensuring operational efficiency, safety, and superior material processing.

Key Features & Innovations

Integrated Bag Breaking & Crushing System: Our unique dual-action design eliminates the need for multiple machines. The process from bag opening to material size reduction happens in one continuous, automated cycle, maximizing throughput and minimizing manual intervention.

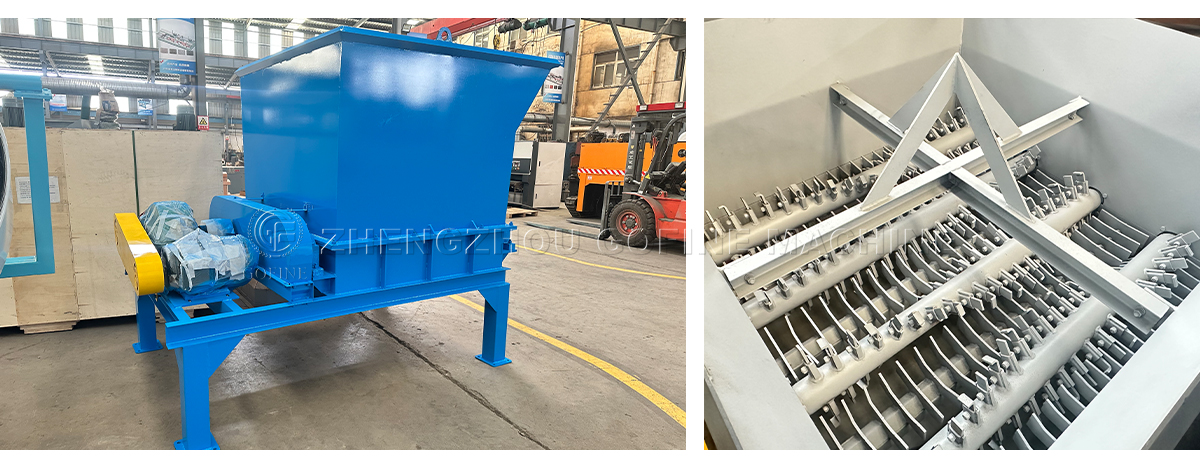

Heavy-Duty Bag Piercing & Shredding Mechanism: Equipped with specially hardened, wear-resistant tools, the top-mounted breaker unit effortlessly pierces and shreds even the toughest FIBCs. This ensures complete discharge of the bag's contents without the risk of bag entanglement.

High-Capacity, One-Second Crushing Action: The heart of the machine features a powerful crushing chamber that processes material in seconds. Its advanced rotor and chamber design delivers immense impact and shear forces, effectively breaking down the hardest agglomerates and lumps.

Crane-Fed Loading for Effortless Handling: The system is designed for seamless integration with overhead cranes or hoists. Operators can simply position the ton bag over the machine's inlet, streamlining the loading process and reducing physical strain.

Rugged Construction for Demanding Environments: Built from high-grade steel and featuring low-maintenance, high-reliability components, the Ton Bag is designed for longevity and continuous operation in harsh industrial settings.

Applications

The Ton Bag Breaker & Crusher is versatile and ideal for a wide range of industries where bulk materials are prone to caking or require size reduction, including:

Fertilizer & Agrochemicals: Breaking up caked urea, NPK, DAP, and other fertilizer blends.

Food & Beverage: Processing lumped sugar, salt, flour, and starch.

Chemicals & Pharmaceuticals: Deagglomerating powdered chemicals, resins, and pharmaceutical raw materials.

Minerals & Pigments: Crushing clumped clay, silica, ores, and colorants.

Plastics & Polymers: Breaking up recycled plastic flakes and polymer pellets.

How It Works: The Four-Step Process

Step 1: Positioning. An overhead crane lifts a ton bag (FIBC) and positions it directly above the inlet of the TitanBag crusher.

Step 2: Bag Breaking & Discharge. The operator initiates the cycle. The integrated bag-breaking unit at the top of the machine activates, piercing the bag and ensuring its contents are fully released. The material falls by gravity into the crushing chamber below.

Step 3: High-Speed Crushing. As the material enters the chamber, the high-speed rotor assembly engages. Utilizing a combination of impact and shear forces, it instantly pulverizes lumps and agglomerates into a uniform, manageable size.

Step 4: Controlled Discharge. The processed, free-flowing material is discharged from the bottom outlet, ready for direct packaging, mixing, or further processing. The entire cycle is fast, efficient.

Let the Ton Bag Breaker & Crusher revolutionize your bulk material handling. Contact us today to discuss your application and request a quote!

Product Details