Manufacturer for Chicken Manure Pellet Machine - Chicken Manure drying machine – Gofine

Manufacturer for Chicken Manure Pellet Machine - Chicken Manure drying machine – Gofine Detail:

Chicken manure dryer is a low-energy, high-efficiency drying equipment, widely used in the rapid drying of high-humidity organic waste materials in livestock and poultry breeding, brewing, sugar, papermaking and other industries, and can reduce the initial moisture content to less than 70% The high-humidity materials are dried at one time to a final moisture content of less than 15%, achieving the purpose of rapid drying and nutrient preservation at one time.

INTRODUCTION

1. Uses and features:

The chicken manure dryer is suitable for the rapid drying of high-humidity materials such as organic fertilizer, corn residue, medicine residue, vinasse residue, pomace, and pasture after fermentation. It has large evaporation and low coal consumption. , The advantages of high drying efficiency. It is equipment for pretreatment of municipal solid waste and drying of feces.

Equipment features: novel design, compact structure, simple operation, high drying efficiency, low operating cost, small footprint; the drum is equipped with a high-speed rotating internal crushing device, which increases the contact area between the material and the drying medium, and the heat It has sufficient mass exchange, good heat preservation and sealing, and its thermal efficiency is much higher than that of ordinary drum dryers. Both drum and crushing device adopt stepless speed regulation, which can adapt to the drying requirements of different materials.

WORKING THEORY

The high-humidity material is directly sent to the chicken manure dryer by the feeding screw conveyor, and is repeatedly picked up and scattered by the copying plate on the inner wall of the drum. After being broken up by the crushing device, the material is fully exposed to the high-temperature medium under negative pressure. Contact to complete the heat and mass exchange process. Due to the inclination angle of the drum and the action of the induced draft fan, the material moves slowly from the feed end, and is discharged by the discharge screw conveyor after drying. The tail gas is discharged by the cyclone dust collector after being dusted.

TECHNICAL-PARAMETERS

| TYPE | D-25 | D-38 |

| POWER KW | 7.5kw | 15KW |

| CAPACITY of waster drying KG/H | 40-50kg/h | 80-120KG/H |

| SIZE M | 3.8×1.5×1.8 | 4.6×1.68×2 |

| PRDUCTION PERIOD | 25 DAYS | 35DAYS |

WORKSHOP ANDCUSTOMERVISIT

Product detail pictures:

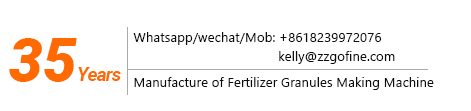

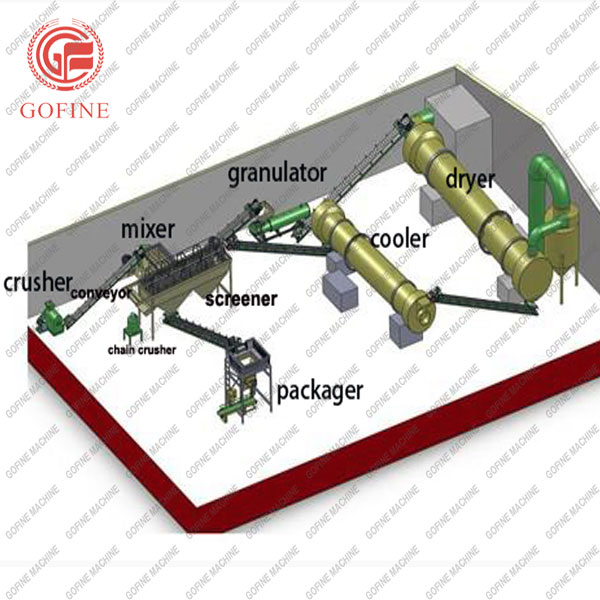

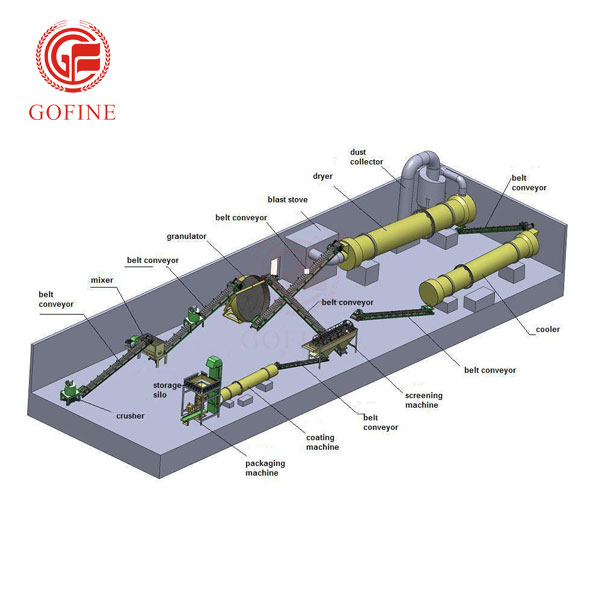

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Manufacturer for Chicken Manure Pellet Machine - Chicken Manure drying machine – Gofine , The product will supply to all over the world, such as: Auckland, Grenada, Danish, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.