Factory wholesale Roller Press Extruder - Rotary Drum Granulating Machine – Gofine

Factory wholesale Roller Press Extruder - Rotary Drum Granulating Machine – Gofine Detail:

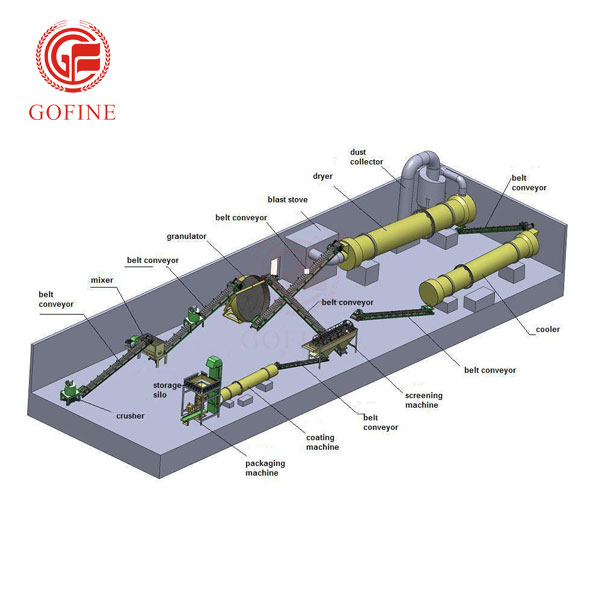

Rotary Drum Granulating Machine can be equipped with steam boiler, ural melting tank and other machine like disk granulator to prouduce different kinds of NPK granules fertilizer and organic fertilizer granules. Its final granules is round ball, diameter 1-5mm, it has more than 90% granulating ratio. It is a good choice for your various fertilizer prouduction.

INTRODUCTION

The barrel of the machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor removal, eliminating the traditional scraper device. This machine has the characteristics of high ball strength, good appearance quality, corrosion resistance, abrasion resistance, low energy consumption, long service life, and convenient operation and maintenance.

The rotating part of the whole body is supported by the bracket and bears a large force. Therefore, the supporting wheel frame part of the machine is welded by medium carbon steel plate and channel steel, and has passed strict quality control and special process requirements. The purpose of the machine. In addition to the more important thing is the bracket fixed on the shelf, because considering that it will produce greater friction with the body rolling belt, our factory deliberately selects anti-corrosion and wear-resistant materials to greatly increase the service life of the machine. Casting integrated technology is also used. In addition, there are hoisting hooks at the four corners of the roller frame, which is convenient for loading and unloading.

FEATURES

1. Low investment, good economic benefits, and reliable performance;

2. Low power, no emissions of three wastes, stable operation, convenient maintenance, reasonable flow layout, and low production cost;

3. High ball strength, good appearance quality, corrosion resistance, abrasion resistance, and low energy consumption;

4. The cylinder body is lined with rubber plate or acid-resistant stainless steel lining, which realizes automatic scar removal and tumor removal, eliminating the traditional scraper device.

TECHNICAL-PARAMETERS

| Type | ZG1240 | ZG1570 | ZG1870 | ZG2080 |

| Working speed | 17rpm | 11.5rpm, | 11.5rpm | 11rpm |

| Final pellet size | Diameter 2-10mm, round shape | |||

| power | 5.5kw | 11kw | 15kw | 18.5kw |

| Dimension | Ø1.2x4mm | Ø1.5x7m | Ø1.8x7m | Ø2x8m |

| Capacity | 1-2t/h | 3-4t/h | 5-7t/h | 10-12t/h |

WORKSHOP AND CUSTOMER VISIT

Product detail pictures:

Related Product Guide:

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Factory wholesale Roller Press Extruder - Rotary Drum Granulating Machine – Gofine , The product will supply to all over the world, such as: Munich, Vancouver, Guatemala, Nowadays our products sell all over the domestic and abroad thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.