Factory Price For Boom Organic Fertilizer - Organic Fertilizer Pelleting Production Line – Gofine

Factory Price For Boom Organic Fertilizer - Organic Fertilizer Pelleting Production Line – Gofine Detail:

Main Raw Materials

ammonium sulfate, ammonium nitrate, ammonium chloride, urea, potassium sulfate, potassium chloride, ammonium phosphate and so on.

Final Granules Fertilizer Standard

China National DB15063-94 standard for your information.

National standards stipulate that the effective nutrient content of compound fertilizer (compound fertilizer), the total amount of high-concentration nitrogen, phosphorus and potassium ≥40%, and the content of low-concentration nitrogen, phosphorus and potassium ≥25%, excluding trace elements and medium elements; water-soluble phosphorus content ≥ 40%, water molecule content is less than 5%; particle size is 1~4.75mm, etc.

Productivity

10000MT/Y, 30000MT/Y, 50000MT/Y, 100000MT/Y, 200000MT/Y

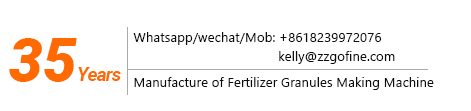

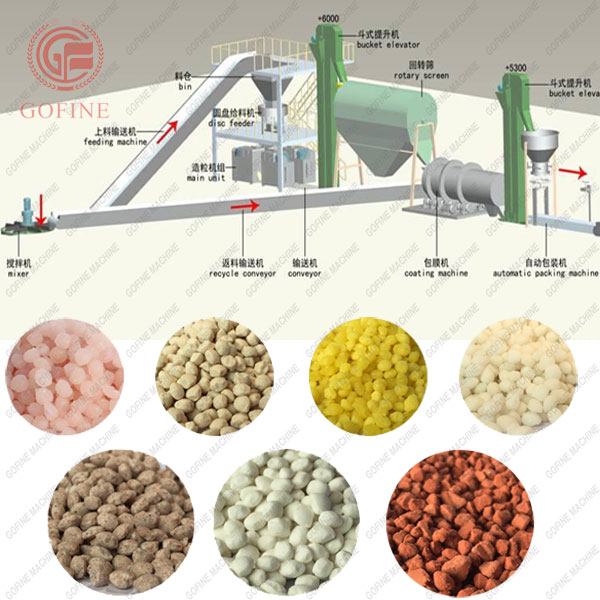

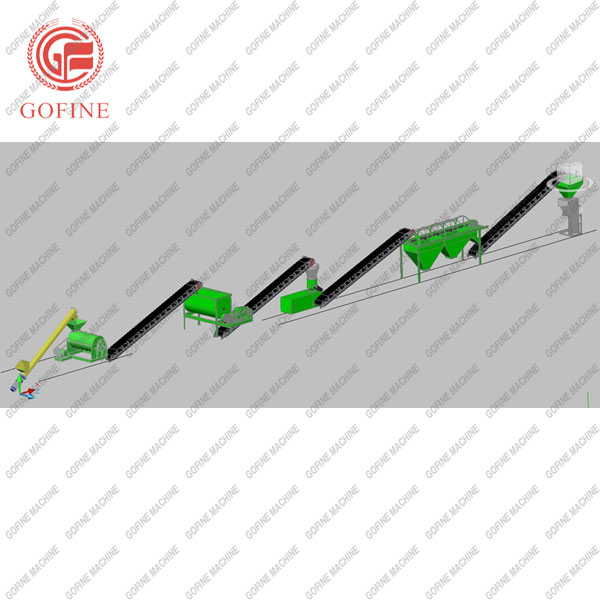

Production Diagram

its main equipment is drum granulating machine, drum dryer and cooler and so on. As the following 30000MT/Y production line listed, it starts from Crushing process to final packing process, including the following fertilizer machinery:

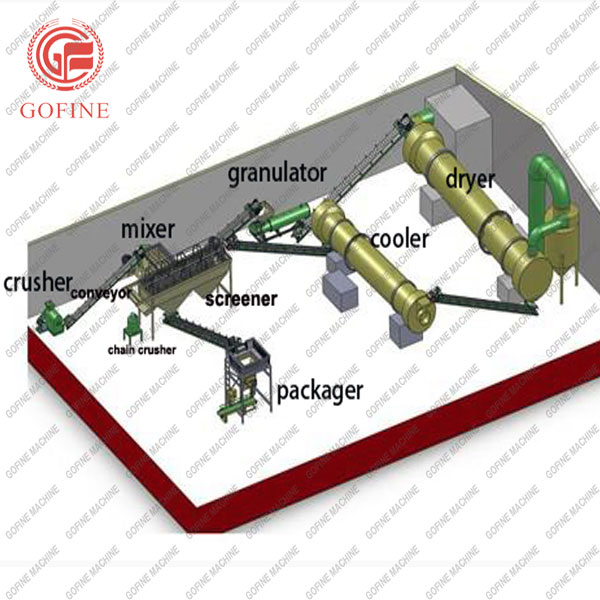

1. raw materials crushing and auto feeding process

1.1. compound fertilizer crusher, like urea crusher, MOP crusher, Cage Crusher, Hammer Crusher, etc. In order to get the fine powder materials.

1.2. auto batching scale feeding and weighing system, normally 4 silos or 6 silos or 8 silos, etc. it can feed different raw materials including the trace elements and other ingredients under the required quantity.

1.3. blending or mixing machine to reach 100% full mixing of each materials.

2. Granulation Process

2.1. drum Granulating machine, equipped with other accessories like boiler, to make the powder into granules.

2.2. dryer and cooler, to strength the granules quickly.

2.3. screening process to get the suitable and popular marketing granules.

2.4. coating process to beautify the final granules, meanwhile to prevent caking in the warehouse.

3. Packing process

3.1 auto packing machine and semi-auto packing machine is chosen according to different capacity.

3.2 Robot Pallet system is optional.

3.3 Film Winding machine to make clean and tidy packing.

Our Factory

Our Factory

Our Factory

Our Factory

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Factory Price For Boom Organic Fertilizer - Organic Fertilizer Pelleting Production Line – Gofine , The product will supply to all over the world, such as: Madras, United Kingdom, Cologne, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.