Granular fertilizer production plays a pivotal role in modern agriculture, providing essential nutrients to crops and enhancing soil fertility. It's a complex process involving various chemical and mechanical operations. Understanding this process is crucial for manufacturers aiming to produce high-quality fertilizers and for farmers seeking to optimize crop yields. This article delves deep into the granular fertilizer production, exploring each step in detail.

Overview of Granular Fertilizer Production

The production of granular fertilizers involves converting raw nutrient materials into granules suitable for agricultural use. It integrates chemical reactions, granulation, drying, cooling, and packaging. Manufacturers must balance efficiency and environmental responsibility throughout this process. We aim to provide a comprehensive understanding of each stage, highlighting critical factors influencing product quality.

Significance in Agriculture

Granular fertilizers are essential for delivering nutrients in a controlled manner. They ensure a slow release of nutrients, matching the crop's growth cycle. This efficiency reduces waste and environmental impact. Farmers rely on these fertilizers to improve yield and soil health. By understanding the production process, stakeholders can make informed decisions about fertilizer selection and application.

Raw Materials Used

Raw materials are the foundation of granular fertilizer production. Key nutrients include nitrogen, phosphorus, and potassium, commonly referred to as NPK. Sources of these nutrients vary:

Additives like micronutrients, fillers, and conditioners are also incorporated to enhance product performance. Quality of raw materials directly affects the efficacy of the final product.

Quality Control of Raw Materials

Ensuring the purity and consistency of raw materials is vital. Contaminants can disrupt chemical reactions and compromise granule integrity. Manufacturers conduct rigorous testing to verify specifications. It safeguards the production process and maintains product standards.

The Granulation Process

Granulation transforms powdered raw materials into uniform granules. This process improves handling, storage, and application of fertilizers. Two primary granulation methods are used: drum granulation and disc (pan) granulation.

Drum Granulation

Drum granulation involves a rotating cylindrical drum where raw materials and binders are introduced. As the drum rotates, particles adhere to each other, forming granules. Factors influencing this process include drum speed, inclination, and moisture content. Control over these variables ensures granule size consistency.

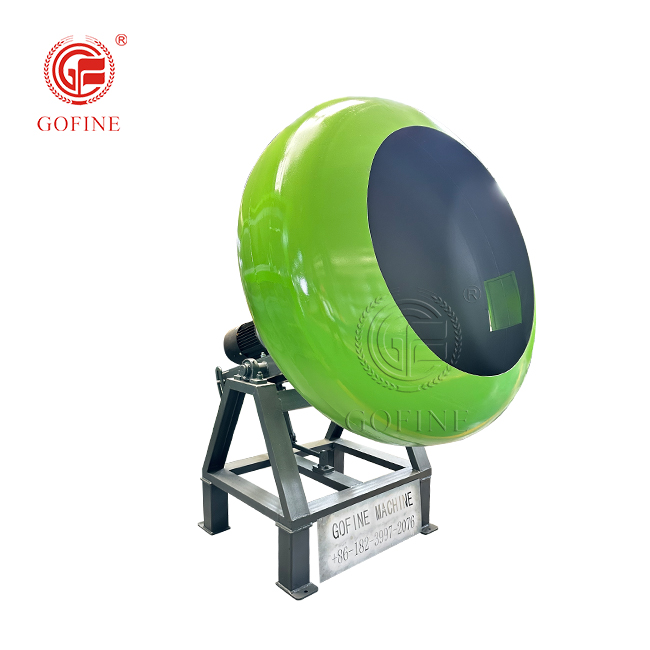

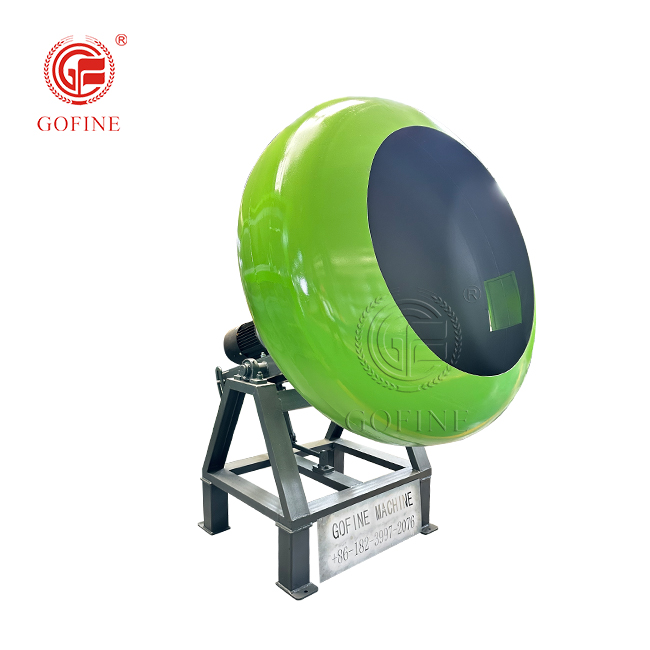

Disc Granulation

In disc granulation, a rotating inclined disc facilitates granule formation. Particles coalesce as they move across the disc surface. Operators adjust the angle and speed to control granule size. It's favored for its simplicity and ability to produce uniform granules.

Chemical Reactions in Granulation

Granulation often involves chemical reactions, especially when producing compound fertilizers. Acid-base reactions create new compounds essential for plant nutrition. Monitoring reaction conditions like temperature and pH is crucial. It ensures complete reactions and prevents unwanted by-products.

Drying and Cooling

Post-granulation, granules contain excess moisture. Drying reduces moisture content to acceptable levels, enhancing storage stability. Rotary dryers are commonly used, leveraging hot air to remove water. Operators must prevent overheating, which can degrade nutrients.

Drying Technologies

Advanced drying technologies optimize energy use. Fluidized bed dryers and flash dryers offer efficient alternatives. They provide uniform drying and can handle various granule sizes. Selection depends on production scale and energy considerations.

Cooling Processes

After drying, granules are cooled to prevent caking and degradation. Cooling systems use ambient or chilled air. Proper cooling maintains granule integrity and prepares the product for packaging. It also improves safety by reducing the risk of combustion in storage.

Screening and Crushing

Granules are screened to separate based on size. Oversized granules are crushed and recycled back into the process. Undersized particles may also be recycled or modified. This step ensures uniformity, which is crucial for consistent nutrient delivery.

Importance of Particle Size

Uniform particle size affects the fertilizer's dissolving rate and spreadability. Consistency prevents segregation during transportation. It ensures that each application delivers the intended nutrient concentration. Quality control teams monitor this closely.

Coating and Conditioning

Some fertilizers receive coatings to enhance performance. Coatings can control nutrient release rates or reduce dust formation. Materials like polymers, sulfur, or clays are applied. The choice depends on the desired fertilizer characteristics.

Controlled-Release Fertilizers

Controlled-release fertilizers release nutrients over an extended period. The coating technology regulates this release. It benefits crops by providing a steady nutrient supply, reducing the need for multiple applications. It also minimizes environmental leaching.

Packaging and Storage

Final products are packaged in bags or bulk containers. Packaging protects the fertilizer from moisture and contamination. Storage conditions are critical. Facilities must be dry and well-ventilated to prevent caking and degradation.

Handling Safety

Fertilizers can be hazardous if mishandled. Safety protocols are established for workers during packaging and storage. Personal protective equipment (PPE) and training reduce risks. Emergency procedures are in place for spills or exposure incidents.

Environmental Considerations

Fertilizer production impacts the environment. Emissions, waste generation, and energy consumption are concerns. Companies adopt measures to mitigate these effects. Compliance with environmental regulations is mandatory.

Emission Controls

Production processes generate emissions like dust and greenhouse gases. Installations of scrubbers, filters, and catalytic converters reduce pollutants. Continuous monitoring ensures adherence to emission standards.

Waste Management

Waste materials include off-spec products and process residues. Recycling within the production process minimizes waste. Proper disposal methods are used for non-recyclable waste. It reduces environmental contamination risks.

Quality Control in Production

Quality control ensures that fertilizers meet specified standards. Testing occurs at various stages, from raw materials to final products. Parameters like nutrient content, moisture, and particle size are assessed.

Laboratory Analysis

Laboratories perform chemical analyses to verify nutrient concentrations. Techniques like spectrometry and titration are used. Accurate measurements are crucial for product labeling and compliance.

Process Control Systems

Modern plants utilize automated control systems. Sensors and software monitor process variables in real-time. Adjustments are made to maintain optimal conditions. It enhances efficiency and reduces human error.

Technological Advancements

Innovation drives improvements in granular fertilizer production. New technologies enhance product performance and sustainability. Advances include precision agriculture integration and smart fertilizers.

Precision Agriculture

Precision agriculture uses data analytics and GPS technology. It guides fertilizer application based on soil variability. Manufacturers are developing fertilizers compatible with precision equipment.

Smart Fertilizers

Smart fertilizers release nutrients in response to environmental triggers. They enhance nutrient use efficiency. Research focuses on coatings that respond to soil moisture or temperature.

Economic Aspects and Market Trends

The fertilizer market is influenced by global agriculture demands. Economic factors like raw material costs impact production. Understanding market trends helps manufacturers adapt strategies.

Global Demand

Population growth drives the need for increased food production. Fertilizer demand rises accordingly. Producers must scale operations while maintaining quality.

Sustainability Trends

There's a shift towards sustainable agriculture. Organic and bio-based fertilizers are gaining popularity. Manufacturers explore eco-friendly production methods.

Conclusion

Granular fertilizer production is a multifaceted process essential for modern agriculture. From raw material selection to technological innovations, each aspect influences the final product's quality and environmental impact. By understanding this process, manufacturers can optimize operations, and farmers can select appropriate fertilizers for their needs. The continuous advancement in this field promises more efficient and sustainable agricultural practices. Embracing these developments in granular fertilizer production will benefit the global food supply chain.

Frequently Asked Questions

1. What are the main raw materials in granular fertilizer production?

The primary raw materials are nitrogen sources (like ammonia or urea), phosphorus sources (such as phosphate rock), and potassium sources (like potassium chloride). Additional micronutrients and conditioners may also be included.

2. How does granulation improve fertilizer efficiency?

Granulation creates uniform particles that ensure even distribution and controlled nutrient release. It enhances handling and reduces nutrient loss, improving overall fertilizer efficiency.

3. Why is quality control crucial in fertilizer production?

Quality control ensures that fertilizers meet nutrient specifications and are free from contaminants. It guarantees product effectiveness and safety for agricultural use.

4. What environmental considerations are associated with fertilizer production?

Environmental considerations include emissions control, waste management, and energy consumption. Responsible practices reduce the environmental impact and comply with regulations.

5. How are controlled-release fertilizers different from regular ones?

Controlled-release fertilizers have coatings that regulate nutrient release over time. They provide sustained nutrition, reduce application frequency, and minimize environmental leaching compared to regular fertilizers.

6. What role does technology play in modern fertilizer production?

Technology enhances production efficiency, product quality, and sustainability. Innovations include automation, precision agriculture integration, and development of smart fertilizers responsive to environmental conditions.

7. How does the global market influence granular fertilizer production?

Global market demands and trends dictate production volumes and innovation focuses. Factors like population growth, sustainable agriculture practices, and economic conditions shape the industry's direction.