Introduction

The professional bone meal fertilizer granulator is an ideal solution for converting raw or processed bone meal into uniform, dust-free and nutrient-rich fertilizer granules. This solves the problems of low efficiency of bone meal fertilizer granulation, dust during production, and inconsistent granule size.

What is bone meal fertilizer?

Bone meal fertilizer is an organic phosphorus-rich substance made from finely ground animal bones. It is an excellent slow-release source of phosphorus (P) and calcium (Ca), which are essential for crop root development, flowering and fruiting.

However, powdered bone meal has some disadvantages:

Difficult to apply evenly

Susceptible to dust contamination

Poor storage and packaging performance

Therefore, many fertilizer merchants began to consider producing bone meal fertilizer granules.

What is a Bone Meal Fertilizer Granulator?

A bone meal fertilizer granulator is a machine designed to convert fine bone meal powder into uniform, round, and durable fertilizer pellets. These granules are easier to store, transport, and apply in the field, without nutrient loss or environmental concerns.

Working Principle of Bone Meal Granulation Equipment

Depending on your production scale and raw material moisture, you can choose from several types of granulators:

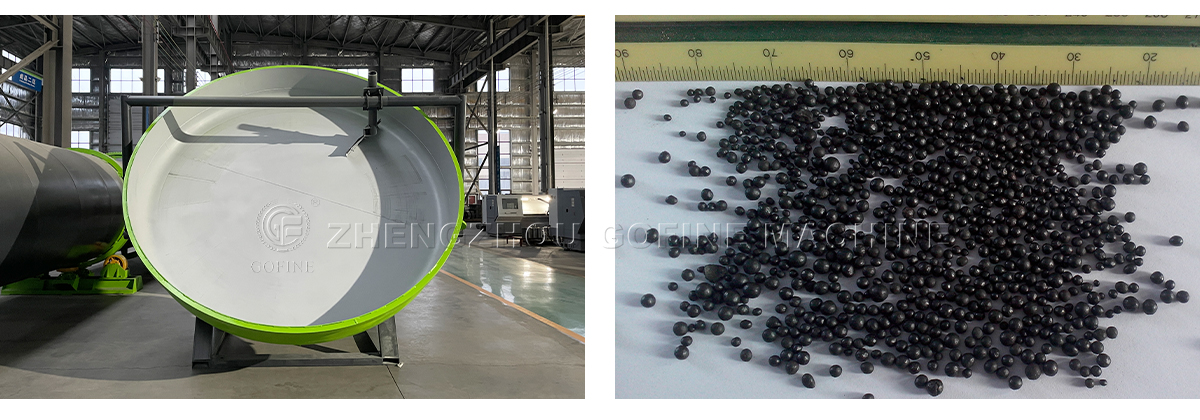

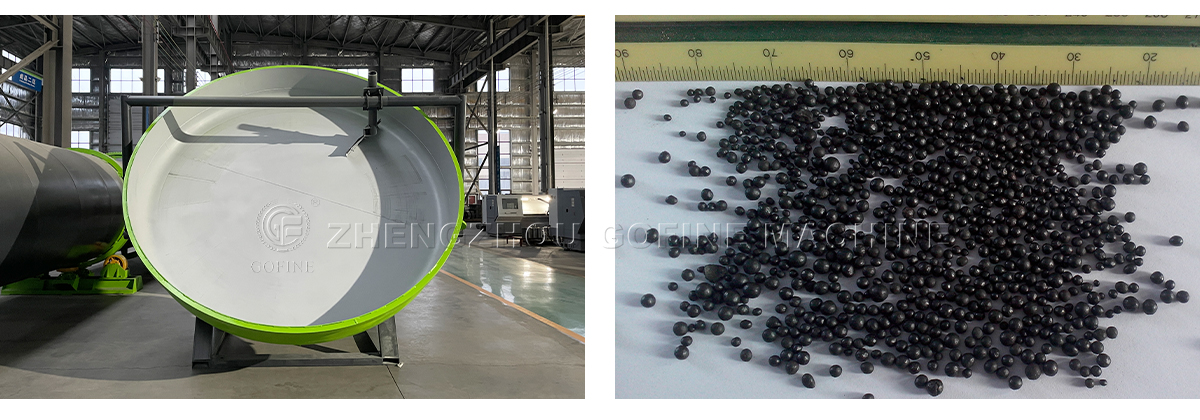

1. Disc Granulator (Pan Granulator)

Ideal for small to medium-scale production

Works best with bone meal mixed with other organic materials

Adjustable angle and moisture content for better shaping

2. Rotary Drum Granulator

Suitable for large-scale bone meal fertilizer production

Ideal for continuous granulation with high output

Requires pre-conditioning and binder addition

3. New Type Organic Fertilizer Granulator (Stirring Tooth Granulator)

Designed for high-moisture organic materials like bone meal

High granulation rate and uniform pellet size

No need for additional binder – relies on mechanical force

4. Double Roller Granulator (Dry Granulation)

Perfect for dry bone meal or low-moisture applications

Forms granules through extrusion – no drying required

Compact and energy-efficient

How to choose a suitable bone meal fertilizer granulator?

When choosing a bone meal granulator, please consider the following factors:

1. Moisture content of raw materials

Wet bone meal? Choose a tooth or drum granulator

Dry bone meal? Choose a double roller granulator

2. Production capacity

Small: disc granulator (500-2000 kg/hour)

Medium and large: drum or organic mixing granulator (5-20 tons/hour or more)

3. Pellet strength requirements

For export or long-distance transportation, please choose high-density granulation

4. Automation requirements

Consider using a PLC control system to achieve fully automatic production

5. Bone meal fertilizer production line

If you need a complete bone meal fertilizer production line, it is recommended that you choose related fertilizer equipment, which will help you achieve automation and scale bone meal fertilizer production. It includes crushers, mixers, granulators, dryers, coolers, sifters, packaging machines, etc.

We are an experienced fertilizer equipment supplier, able to provide you with professional services, including:

Complete bone meal fertilizer production line design

High-efficiency, long-life granulator

Technical support, installation and training

Customized solutions based on your production capacity and budget

Contact me now to get a free quote and solution design.

Look forward to our cooperation!