Fertilizer production plays a crucial role in modern agriculture, helping farmers increase crop yields and improve soil fertility. A fertilizer production line is a complete system designed to produce various types of fertilizers, including organic, inorganic, compound, and bio-fertilizers. Whether you're setting up a small-scale operation or a large industrial plant, understanding the key components of a fertilizer production line is essential for ensuring efficiency, quality, and productivity.

This article will break down the main components of a fertilizer production line, explaining their roles and how they work together to create the perfect fertilizer for agricultural use. We'll also compare different types of production lines to help you make informed decisions when choosing the right equipment for your needs.

1. Raw Material Preparation

Raw Material Storage and Handling

The first step in any fertilizer production process involves preparing the raw materials. The quality of the raw materials directly impacts the final fertilizer product. Common raw materials used in the production of fertilizers include nitrogen, phosphorus, potassium, sulfur, and various organic components such as compost or manure.

The raw material storage facilities should be designed to handle a large volume of different materials. These materials need to be stored in silos or warehouses where they can be kept safe from contamination, moisture, or exposure to the elements. Proper storage systems prevent degradation and ensure consistency in the production process.

Material Blending and Mixing

Before the raw materials can be processed into fertilizer, they often need to be blended or mixed to create a uniform consistency. This can be done using mixers or blending machines, which are essential for ensuring that all components are evenly distributed. For example, when producing compound fertilizers, nitrogen, phosphorus, and potassium must be evenly mixed to ensure that each fertilizer pellet contains the right balance of nutrients.

2. Granulation and Pelletizing

Granulation is the process of turning raw materials into granules or pellets, which are easier to handle, store, and apply. The granulation system in a fertilizer production line is critical for producing high-quality granular fertilizers that have good flowability and consistency.

Granulation involves several key stages:

Mixing: After the raw materials are blended, they are combined with water or binding agents to form a slurry.

Pelletizing: The slurry is then fed into a granulator, where it is shaped into small, uniform pellets.

Drying and Cooling: After pelletizing, the pellets must be dried to reduce their moisture content and make them stable for storage. This is achieved through a dryer that uses hot air to evaporate the moisture. Cooling is then done to prevent caking during storage.

The most common granulation methods include:

3. Coating and Drying

After granulation, some fertilizers, especially those with slow-release properties, require coating to improve their effectiveness. Coating machines apply a thin layer of protective material over the granules. This process can help control the release rate of nutrients, ensuring that they are available to plants over an extended period.

Once the coating process is complete, the granules are sent to the dryer for further moisture removal. The drying process is crucial for ensuring that the final product is free from moisture, preventing clumping or degradation.

4. Screening and Sieving

Not all granules created in the granulation process are of uniform size. Therefore, a screening and sieving system is used to separate granules based on size. The smaller and larger granules are separated, with the ideal-sized granules being collected for packaging.

The screening process helps remove dust and ensures that only properly sized granules make it to the next stages of the production line. This helps maintain the overall quality of the fertilizer, ensuring that only the best products reach customers.

5. Packaging and Storing

Once the fertilizer has been granulated, dried, coated, and screened, it is ready for packaging. The packaging system can be automated or manual, depending on the scale of the operation. Automated packaging systems often include weighers, baggers, and sealers that can package fertilizers in various sizes, from small bags for retail sales to large bulk bags for industrial use.

After packaging, the fertilizer is stored in a warehouse before being shipped to customers or distributors. The storage area should be climate-controlled to prevent moisture buildup or contamination of the final product.

6. Fertilizer Quality Control

Quality control (QC) is a crucial component of any fertilizer production line. QC ensures that the final product meets the desired specifications and complies with industry standards. It typically includes:

Laboratory testing: Samples are taken at various stages of the production process and tested for nutrient content, moisture levels, and physical properties.

Visual inspection: Operators inspect the appearance of the fertilizer granules, looking for irregularities or defects.

Performance testing: In some cases, the effectiveness of the fertilizer may be tested by applying it to plants and measuring growth results.

By maintaining rigorous quality control practices, fertilizer manufacturers ensure that their products deliver the desired results for customers.

7. Automation and Control Systems

Modern fertilizer production lines are equipped with sophisticated automation and control systems to improve efficiency, reduce human error, and increase production capacity. These systems monitor and control various aspects of the production process, such as:

Raw material handling and feeding rates

Temperature and humidity levels in the drying and cooling sections

Granulation parameters, such as mixing speed, moisture content, and pellet size

Packaging and labeling

A centralized control system allows operators to monitor and adjust all stages of the production process from one location, ensuring smooth and continuous production.

8. Maintenance and Support

Regular maintenance is essential to keep the fertilizer production line operating at peak efficiency. Maintenance services include:

Routine inspections to check for wear and tear

Lubrication of moving parts

Replacement of worn-out components, such as screens, belts, and bearings

Many fertilizer production line suppliers, such as Zhengzhou Gofine Machine Equipment Co., Ltd., offer comprehensive after-sales support, including maintenance services and spare parts, to ensure the long-term stability and efficiency of the equipment.

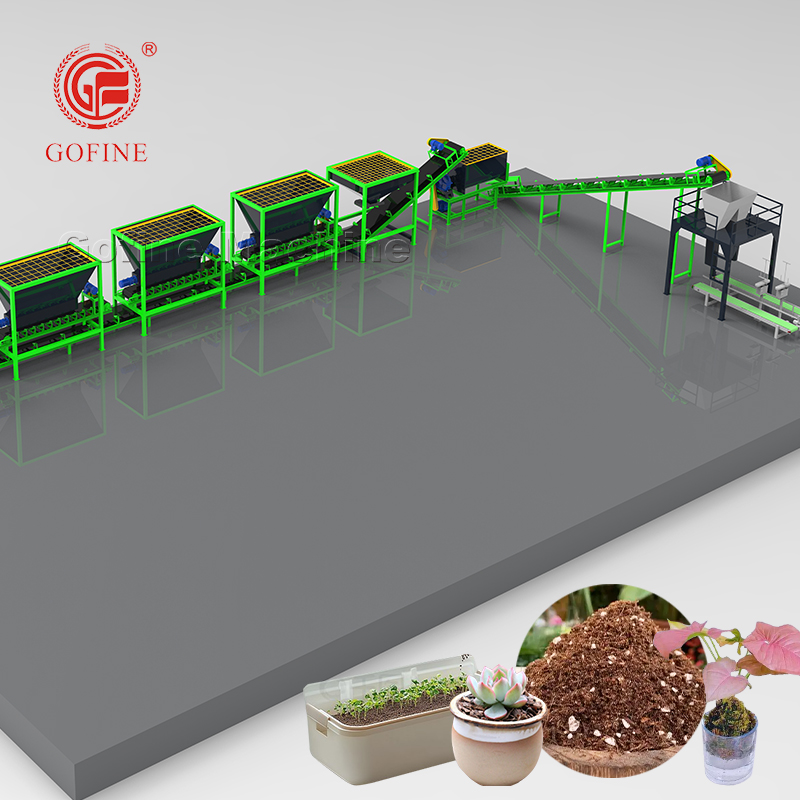

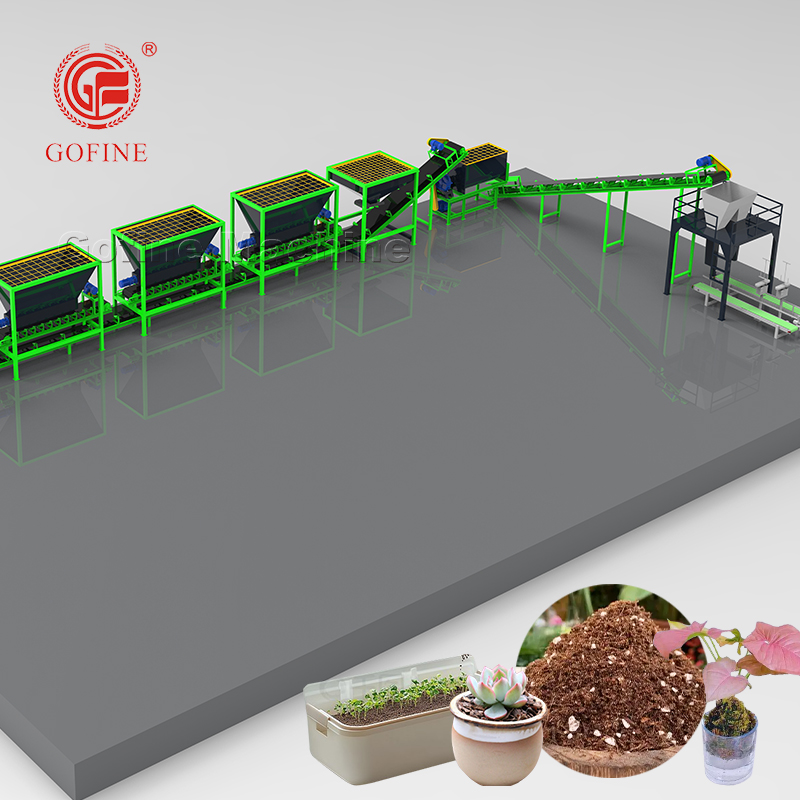

Types of Fertilizer Production Lines

There are different types of fertilizer production lines, each designed for specific needs and scales of production. The main types include:

This type of line processes organic materials, such as animal manure, compost, and plant residues, into organic fertilizer. It typically includes a composting machine, mixing machine, granulator, dryer, and packing system.

Compound fertilizer production lines are used to create fertilizers that combine two or more nutrients, such as NPK fertilizers (nitrogen, phosphorus, and potassium). This line typically includes a batching system, mixers, granulators, dryers, and coolers.

3. Bio-fertilizer Production Line

Bio-fertilizer lines are designed to process bio-organic materials and microbes to create fertilizers that promote soil health. The production line includes a fermentation tank, bio-fertilizer granulator, and packaging system.

4. BB Fertilizer Production Line

BB (Bulk Blending) fertilizer lines are used for blending different raw materials into bulk fertilizers. This line uses a batching system, mixers, and screening equipment to create customized fertilizers based on specific crop needs.

Conclusion

The fertilizer production line is a complex system that integrates various machines and technologies to create fertilizers that are essential for modern agriculture. From raw material preparation to packaging and quality control, each component of the production line plays a crucial role in ensuring high-quality fertilizers.

When choosing a fertilizer production line, it's important to consider factors like production capacity, raw material type, and automation options. Leading suppliers like Zhengzhou Gofine Machine Equipment Co., Ltd. offer a wide range of customizable solutions that can help businesses optimize their fertilizer production process and improve operational efficiency.

FAQs

1. What is the role of granulation in fertilizer production?

Granulation is a key process that turns raw materials into small, uniform granules that are easier to handle and apply to crops.

2. How does automation improve fertilizer production lines?

Automation helps increase efficiency, reduce errors, and enhance production capacity by controlling various parameters such as mixing speed, moisture content, and pellet size.

3. What maintenance is required for a fertilizer production line?

Regular maintenance includes inspections, lubrication, and replacement of worn parts to ensure that the production line operates smoothly and efficiently.