Overview

Our Integrated Smart-Cover Aerobic Composting System is a turnkey, mechanized platform that redefines efficiency and control in organic waste recycling. More than just a cover, it is an engineered ecosystem combining a semi-permeable functional membrane with a dedicated self-propelled handler. This synergy transforms open-air windrowing into a precise, odor-managed, and weather-independent biological process. Designed for municipalities, large-scale farms, and commercial processors, it consistently converts sludge, manure, and agri-food waste into high-grade compost in record time, ensuring environmental compliance and superior product stability with minimal operational overhead.

Features

The smart membrane acts as a molecular filter, trapping odors (ammonia, VOCs) inside while letting vapor out. Enables operation near residential areas and ensures regulatory compliance.

Maintains a perfect, self-regulated climate (55-70°C) to supercharge microbial activity. Achieve complete primary fermentation in 3-4 weeks for faster, predictable output year-round.

Our integrated cover handler & turner performs the full sequence: uncovers, turns/aerates, and re-covers the pile in a single pass. Dramatically reduces labor and fuel costs.

The impermeable membrane blocks all rain/snow to prevent runoff, while locking in heat and moisture. Eliminates weather delays and reduces water/energy needs.

Guarantees sustained high temperatures to eliminate pathogens and weeds. Yields a consistent, stable, and mature compost ready for sensitive horticultural use.

Applications

This system is engineered for entities requiring scalable, clean, and efficient organic waste valorization:

Municipal Solid Waste & Biosolids Management: For large-scale municipal composting facilities processing green waste and wastewater sludge.

Intensive Livestock Farming: Ideal for centralized manure composting for dairy, poultry, and swine, managing high volumes with neighbor-friendly odor control.

Food & Organic Waste Recycling Plants: Processes commercial food waste, supermarket organics, and source-separated residential waste into quality compost.

Landscaping & Soil Blending Facilities: Produces consistent, high-quality compost and topsoil blends for professional use.

Work Process

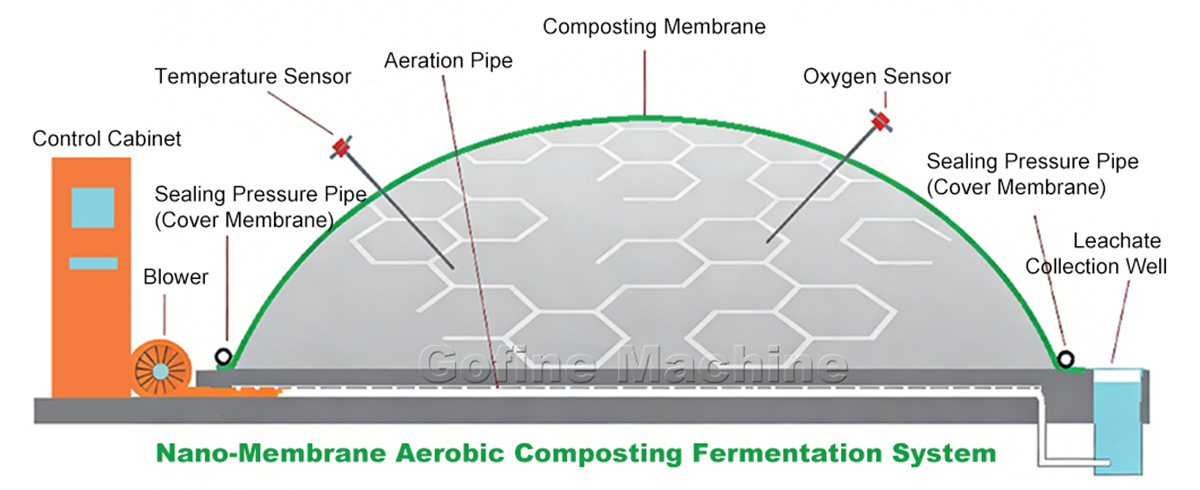

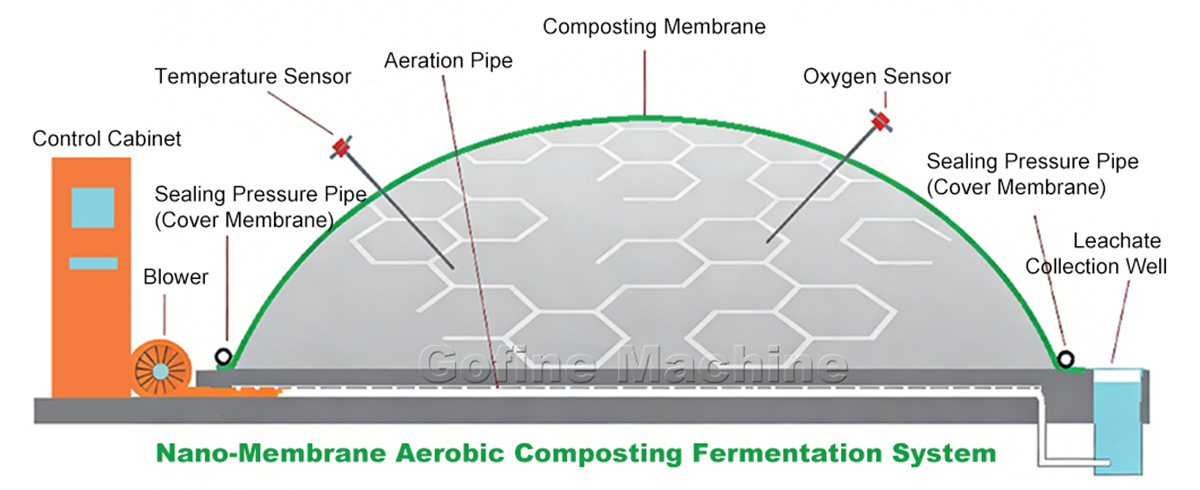

Preparation & Pile Formation: Pre-processed feedstock is formed into elongated windrows on a hardstand with an integrated aeration grid.

Initial Covering: The self-propelled handler is used to quickly unroll and deploy the smart membrane over the fresh pile.

Active, Monitored Fermentation: A blower system provides forced aeration. The membrane manages the internal atmosphere, releasing CO₂ and vapor while containing odors. Temperatures are monitored remotely.

Integrated Turning & Re-Covering: At scheduled intervals, the handler machine executes the unified process of uncovering, turning/aerating the compost, and re-covering the windrow in a single, efficient operation.

Curing & Finishing: After several cycles, the stabilized compost is uncovered for a short curing phase before final screening and shipment.

Technical Parameters

Product photos

Organic Fertilizer Production Line

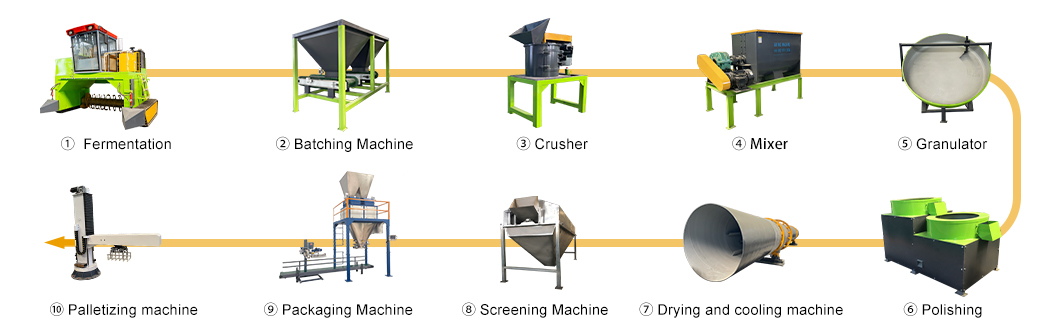

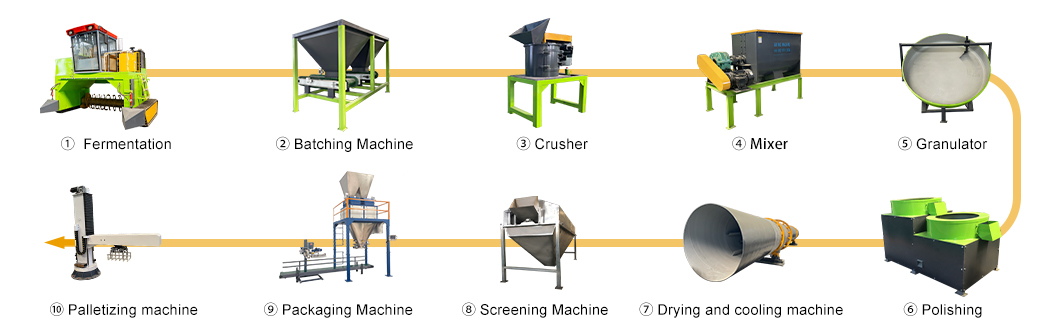

Within a comprehensive commercial organic fertilizer manufacturing plant, this system serves as the guaranteed, high-capacity primary bio-stabilization reactor. It reliably and rapidly transforms variable raw waste into a sanitized and stabilized intermediate product. This uniform pre-compost is the essential foundation for all downstream value-adding processes, including:

Secondary Curing & Refinement

Precise Crushing, Screening, and Sizing

Nutrient Fortification and Custom Blending

Granulation for premium fertilizer production

Bagging and Packaging

By ensuring a rapid, controlled, and high-quality first-stage process, it optimizes feedstock consistency for granulation and enhances the overall efficiency, output, and profitability of the entire fertilizer production chain.

Ready to eliminate odor complaints, boost your composting throughput, and reduce operational costs? Unlock the potential of your organic waste stream. Contact us today for a detailed consultation, customized system quote, or to request a case study from a facility like yours. Let's discuss how our integrated system can transform your operation.