As a professional fertilizer equipment manufacturer with over 30 years of experience, we understand that getting accurate chemical fertilizer granules making machine quotesis crucial for your investment decisions. Whether you're establishing a new production facility or upgrading existing equipment, having comprehensive information about fertilizer making machine options and pricing will help you make informed choices for your NPK fertilizer production business.

Understanding Chemical Fertilizer Granules Production Process

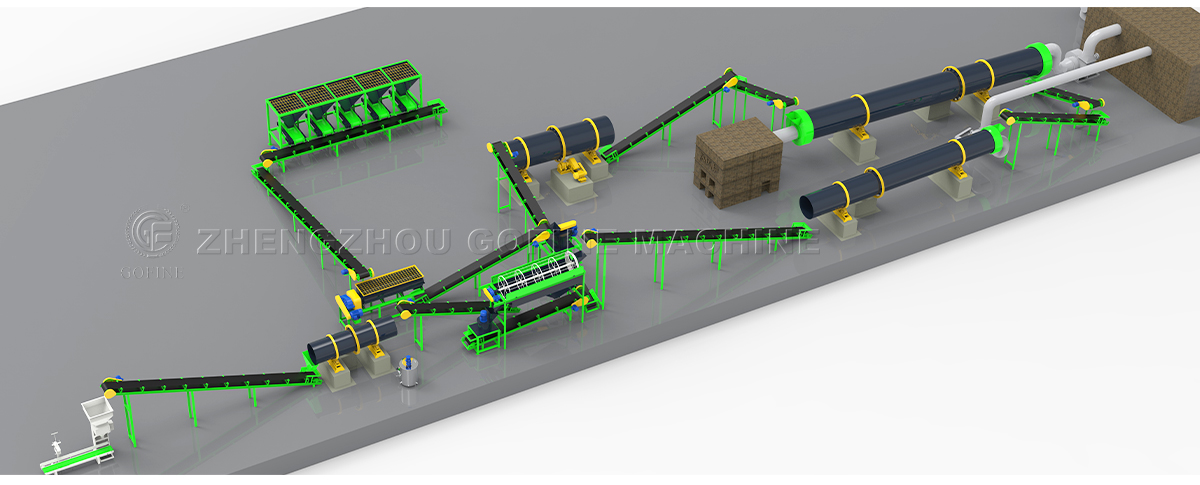

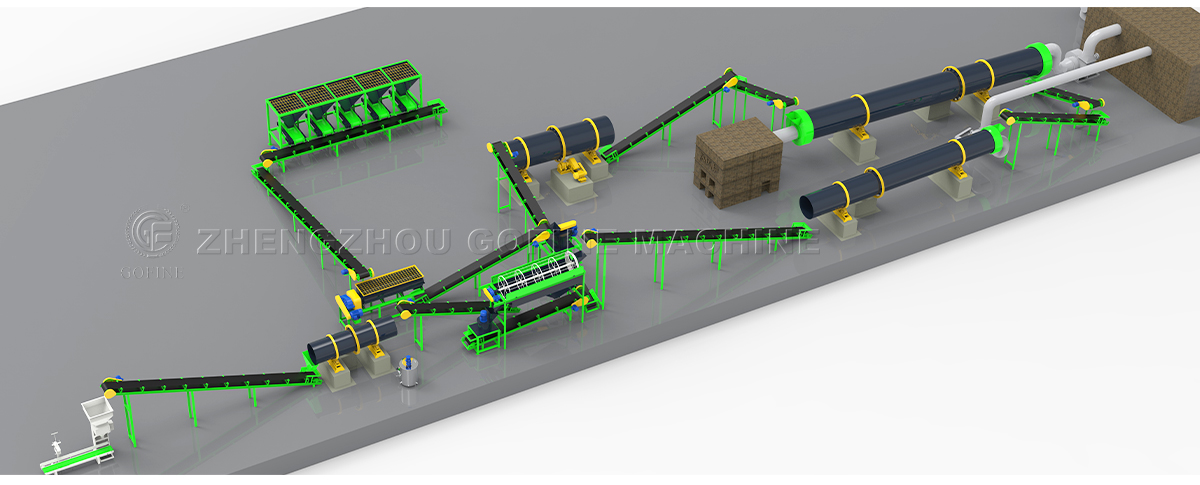

The production of chemical fertilizer granules involves several interconnected processes, each requiring specialized equipment. A complete fertilizer granules making machine setup typically includes:

·Raw Material Preparation System

Crushers: Pre-treatment equipment for reducing raw material size

Sieves: Screening machines for material classification

Feeding Systems: Automated conveyors for material handling

·Mixing and Blending Section

Horizontal Mixers: For homogeneous blending of NPK materials

Weighing Systems: Precision batching equipment

·Granulation Process - Core Equipment

The fertilizer granulator forms the heart of your production line. We offer multiple technologies:

1. Rotary Drum Granulators

Capacity: 1-30 tons per hour

Suitable for large-scale production

Steam granulation capability

Low operating costs

2. Double Roller Extrusion Granulators

No drying process required

High-density granule production

Energy-efficient operation

Minimal maintenance requirements

3. Disc Granulators

Adjustable pellet size (2-8mm)

Visual process monitoring

Easy operation and maintenance

Cost-effective solution

·Drying and Cooling System

Rotary Dryers: Reduce moisture content to optimal levels

Cooling Machines: Stabilize granules for storage and packaging

Heat Recovery Systems: Energy-efficient operation

·Finished Product Processing

Screening Machines: Size classification and quality control

Coating Machine: Surface treatment for improved quality

Packaging Machines: Automated weighing and bagging systems

Factors Influencing Chemical Fertilizer Machine Quotes

When requesting fertilizer granulator quotes, consider these key factors that affect pricing:

Small scale: 1-5 tons per hour

Medium scale: 5-15 tons per hour

Large scale: 15-30+ tons per hour

Basic manual control systems

Semi-automatic operation

Fully automated PLC-controlled plants

Material of construction (carbon steel vs stainless steel)

Motor brands and power efficiency

Control system sophistication

Safety features and certifications

Installation and commissioning

Operator training

Warranty period and terms

After-sales service support

Why Choose Our Fertilizer Making Machines?

Our chemical fertilizer machine range incorporates:

Advanced granulation technology

Energy-efficient designs

Robust construction for continuous operation

User-friendly control systems

We tailor each fertilizer granules making machine to your specific:

Raw material characteristics

Production capacity requirements

Factory layout constraints

Budget considerations

Request Your Customized Quote Today!

Contact our technical team for detailed chemical fertilizer granules making machine quotes tailored to your specific needs. We provide:

Comprehensive equipment proposals

Factory layout designs

Investment return analysis

Project implementation plans