Overview: Streamline Your Fertilizer Packaging Line with Precision Automation

For fertilizer producers, the final packaging stage is critical. Manual bagging is slow, inconsistent, and labor-intensive, creating bottlenecks that limit production output and profitability. Inaccurate weights can lead to significant product giveaway or customer complaints, while dust and spillage create a messy, wasteful, and potentially hazardous work environment.

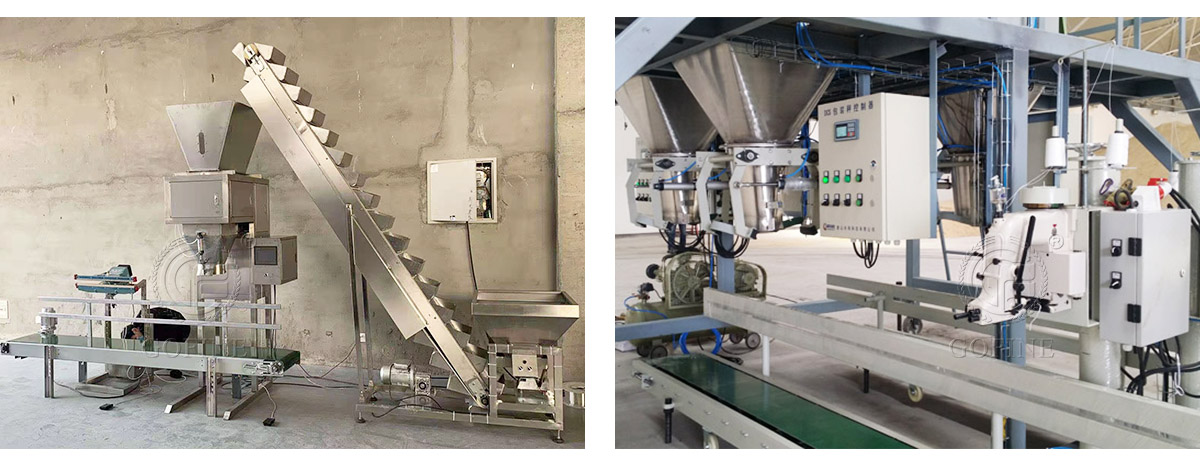

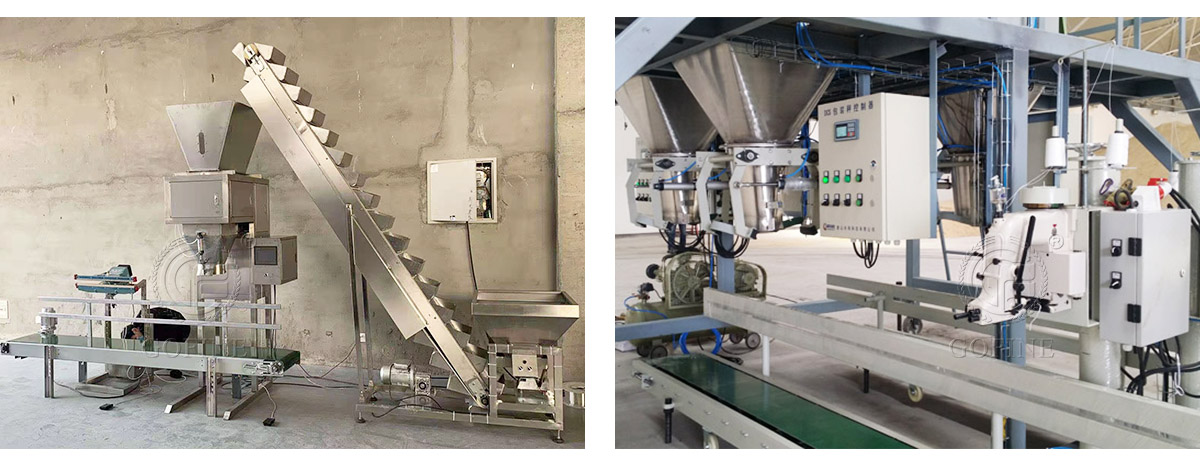

The GoFine Automatic Fertilizer Bagging Packaging Machine is engineered to eliminate these challenges. This robust automatic weighing and bagging machine integrates seamlessly into your production line, delivering unmatched speed, precision, and reliability for packaging a wide range of fertilizer materials—from powdered and crystalline to granular and prilled products. It’s the smart investment for businesses looking to scale up, reduce costs, and ensure a consistently professional final product.

What problems can Gufeng packaging machines help you solve?

1. Problem: Slow, inconsistent manual bagging creates production bottlenecks.

Solution: Our automatic bagging system provides continuous, high-speed operation, dramatically increasing output (bags/hour) and eliminating this key constraint.

2. Problem: Inaccurate bag weights result in product loss (giveaway) or underweight penalties.

Solution: Featuring a high-precision weighing and filling machine with advanced load cell technology, it ensures each bag meets the exact target weight, maximizing your yield and compliance.

3. Problem: High labor costs, physical strain, and difficulty finding reliable workers for manual packing.

Solution: Automation drastically reduces labor dependency. One operator can manage multiple machines, handling only bag placement or supervision, lowering long-term costs and ergonomic risks.

4. Problem: Dust pollution and product spillage during filling, harming worker health and creating waste.

Solution: Designed with dust control features such as sealing systems and optional dust collection ports, it maintains a cleaner, safer, and more sustainable workplace.

5. Problem: Difficulty packaging different fertilizer types (powder, granules, blends) on the same line.

Solution: Our versatile fertilizer packaging equipment is adjustable and can handle various materials with simple setting changes, offering exceptional flexibility for multi-product facilities.

Why Choose the GoFine Automatic Fertilizer Packaging System?

Unmatched Precision Weighing: At its core is a sensitive, shock-resistant weighing system that guarantees high weighing accuracy (typically within ±0.1%-0.2%), protecting your profit margin.

Rugged & Reliable Construction: Built for the demanding fertilizer industry with heavy-duty materials and components, ensuring 24/7 durability, minimal downtime, and a long service life in dusty environments.

User-Friendly Operation: The intuitive touch-screen PLC control system allows for easy setup of parameters like target weight, bag count, and speed. Operators can be trained quickly.

Flexible & Adaptable Design: Compatible with various bag types (open-mouth bags, valve bags) and bag sizes (5kg to 50kg). Customizable with options like automatic bag placers, conveyor belts, and sewing/sealing stations.

High-Speed Efficiency: Engineered for rapid, continuous cycling, our automatic packaging line component significantly boosts your overall plant throughput and capacity.

Easy Maintenance: Easy-access design and standardized components simplify routine cleaning and maintenance, keeping your line running smoothly.

Applications

Granular Fertilizers: NPK compounds, urea, DAP, MAP, potassium chloride.

Powdered Fertilizers: Single superphosphate, lime, powdered blends.

Organic & Biofertilizers: Compost pellets, manure-based fertilizers, microbial products.

Soil Amendments: Gypsum, limestone granules.

Animal Feed Pellets: Related agri-processing.

Technical parameters

| Product Name | Open semi-auto granules packing scale |

| Packing arrange | 5-50kg/bag |

| Max weighing scale | 100kg |

| Bagging speed | 4-6 bags per min |

| Accuracy | ±0.2% |

| Air pressure | 0.4-0.6Mpa |

| power | 0.75-2.2kw, 220/380v, single phase |

| size | 0.8x0.9x2.7m |

How It Works: The Automated Bagging Process

Bag Placement: An operator hangs an empty bag on the filling spout, or an optional automatic bag placer robotically positions it. The bag is securely clamped.

Weighing & Filling: Upon command, the machine's high-speed auger filler or gravity feed system activates. Material is fed into the bag while the integrated scale continuously monitors the weight in real-time.

Precision Cut-off: As the weight approaches the preset target, the system switches to a slow "dribble" feed for final accuracy, then completely cuts off the flow at the exact weight.

Bag Release & Sealing: The bag clamps release. The filled bag drops onto a take-away conveyor, which transports it to the next station for sewing, heat sealing, or palletizing, completing the automatic packaging process.

Our Service & Support

As your trusted fertilizer equipment supplier, GoFine provides more than just machinery—we deliver a complete partnership for your success.

Free Technical Consultation: We analyze your production needs, material characteristics, and output goals to recommend the optimal machine configuration.

Comprehensive Installation & Commissioning: Our engineers ensure the machine is perfectly integrated into your line and calibrated for peak performance.

Detailed On-Site Training: We train your staff thoroughly on operation, routine maintenance, and basic troubleshooting.

Quality Spare Parts Guarantee: Genuine spare parts are readily available to ensure long-term machine health and performance.

Responsive After-Sales Support: Our dedicated service team provides prompt remote and on-site support to maximize your uptime and return on investment.

Conclusion

Upgrade your production capability with the GoFine Automatic Fertilizer Bagging Packaging Machine. It is the definitive solution for achieving precision, efficiency, and cleanliness in your packaging operations. By automating this critical stage, you directly reduce costs, increase output, enhance product quality, and strengthen your competitive edge in the market. Contact us today to find the perfect packaging solution for your plant.