Fertilizers play a crucial role in modern agriculture by enhancing soil fertility and boosting crop yields. Understanding the raw materials used in fertilizer production is essential for optimizing agricultural practices and ensuring sustainable food production. This article delves into the various raw materials that form the backbone of fertilizer manufacturing, exploring their sources, properties, and contributions to plant nutrition. By examining these components, we gain insight into the complexities of granular fertilizer production and its impact on global agriculture.

Primary Nutrients in Fertilizer Composition

The primary nutrients essential for plant growth are nitrogen (N), phosphorus (P), and potassium (K). These elements are the foundational raw materials in most fertilizers, often referred to as NPK fertilizers. Each nutrient serves specific functions in plant development, and their availability in the soil determines crop productivity.

Nitrogen Sources

Nitrogen is vital for protein synthesis and overall plant growth. The raw materials for nitrogen in fertilizers include ammonia, ammonium nitrate, urea, and ammonium sulfate. Ammonia is typically produced through the Haber-Bosch process, which combines nitrogen from the air with hydrogen derived from natural gas under high pressure and temperature. Urea, another significant nitrogen source, is synthesized from ammonia and carbon dioxide.

Phosphorus Sources

Phosphorus is essential for energy transfer and genetic material formation in plants. The primary raw material for phosphorus fertilizers is phosphate rock, a sedimentary rock rich in phosphate minerals. Processing phosphate rock with sulfuric acid produces phosphoric acid, which is then used to manufacture various phosphorus fertilizers like monoammonium phosphate (MAP) and diammonium phosphate (DAP).

Potassium Sources

Potassium regulates water uptake and enzyme activity in plants. Potash, a term derived from "pot ash," refers to potassium-bearing minerals and salts. The primary raw materials for potassium fertilizers are potassium chloride (KCl), potassium sulfate (K2SO4), and potassium nitrate (KNO3). These compounds are extracted from ancient evaporated sea beds and brine solutions through mining and processing.

Secondary and Micronutrient Raw Materials

While NPK nutrients are critical, plants also require secondary nutrients and micronutrients in smaller quantities. These elements include calcium (Ca), magnesium (Mg), sulfur (S), iron (Fe), manganese (Mn), zinc (Zn), copper (Cu), molybdenum (Mo), boron (B), and chlorine (Cl).

Sources of Secondary Nutrients

Secondary nutrients are obtained from raw materials like gypsum (calcium sulfate) for calcium and sulfur, dolomite (calcium magnesium carbonate) for magnesium and calcium, and elemental sulfur. These materials enhance soil structure, nutrient uptake, and crop quality.

Micronutrient Sources

Micronutrients are derived from inorganic salts and chelates. Common raw materials include zinc sulfate for zinc, ferrous sulfate for iron, copper sulfate for copper, and sodium molybdate for molybdenum. Incorporating these elements into fertilizers corrects soil deficiencies, promoting healthy plant development.

Organic Fertilizer Raw Materials

Organic fertilizers are derived from natural sources and play a pivotal role in sustainable agriculture. They improve soil structure, increase microbial activity, and provide a slow-release source of nutrients.

Animal Manure

Animal manure from livestock like cattle, poultry, and swine contains essential nutrients and organic matter. It is processed through composting to stabilize the material and eliminate pathogens. Composting enhances nutrient content and availability to plants.

Plant Residues

Crop residues, green manures, and cover crops are valuable raw materials. They are incorporated back into the soil, enriching it with organic matter and nutrients. This practice reduces the need for synthetic fertilizers and enhances soil health.

Seaweed and Fish Emulsions

Seaweed extracts and fish emulsions are rich in micronutrients and growth hormones. Harvesting seaweed and processing fish byproducts create liquid fertilizers that stimulate plant growth and improve stress resistance.

Synthetic Fertilizer Manufacturing Processes

The production of synthetic fertilizers involves chemical reactions and industrial processes. Understanding these methods offers insight into the transformation of raw materials into usable fertilizers.

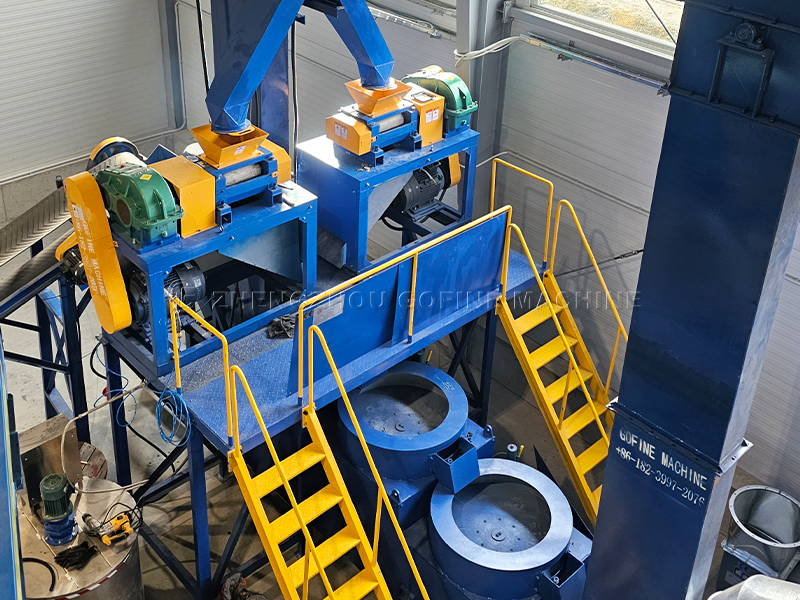

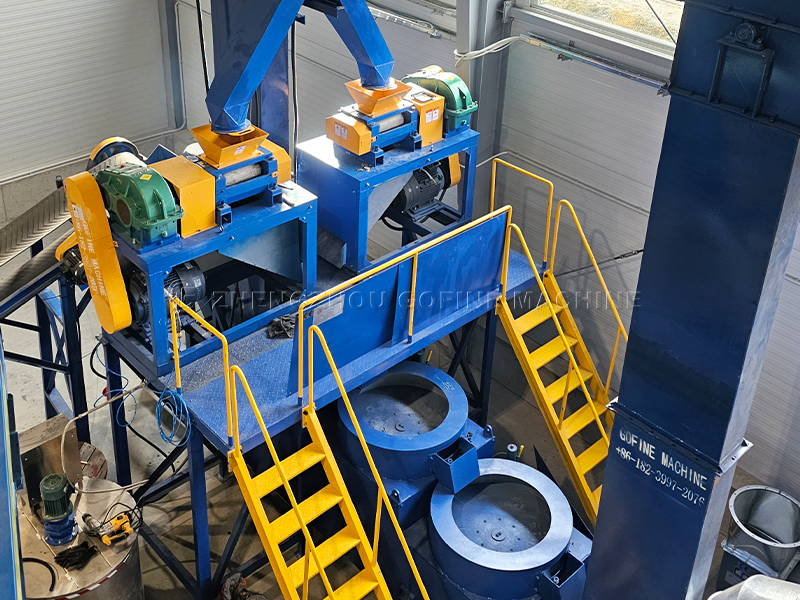

Granulation Techniques

Granulation converts fine raw materials into granular fertilizer particles. It improves handling properties and nutrient distribution. Techniques include drum granulation, disc granulation, and compaction. These methods are integral to granular fertilizer production and influence the effectiveness of fertilizer application.

Chemical Synthesis

Chemical synthesis involves reactions between raw materials to form nutrient-rich compounds. For example, reacting ammonia with phosphoric acid produces ammonium phosphate fertilizers. These processes require precise control of reaction conditions to ensure product quality.

Environmental Considerations

Fertilizer production and use have environmental impacts. Responsible sourcing of raw materials and sustainable manufacturing practices are essential for mitigating negative effects.

Resource Depletion

Phosphate rock and potash deposits are finite resources. Over-reliance on these raw materials raises concerns about future availability. It prompts the exploration of alternative sources and recycling nutrients from waste streams.

Energy Consumption

Fertilizer manufacturing is energy-intensive, particularly nitrogen production via the Haber-Bosch process. It consumes significant amounts of natural gas, contributing to greenhouse gas emissions. Innovations in energy efficiency and renewable energy integration are critical.

Pollution and Runoff

Excessive fertilizer application leads to nutrient runoff, causing water pollution and eutrophication. Developing controlled-release fertilizers and promoting best management practices reduce environmental risks.

Innovations in Fertilizer Raw Materials

The fertilizer industry is evolving with new technologies and raw materials aimed at sustainability and efficiency.

Biofertilizers

Biofertilizers utilize microorganisms to enhance nutrient availability. These include nitrogen-fixing bacteria, phosphate-solubilizing fungi, and mycorrhizal fungi. Cultivating these organisms as raw materials supports eco-friendly agriculture.

Nanofertilizers

Nanotechnology introduces nanoparticles as carriers of nutrients, improving absorption and reducing losses. Raw materials include nano-sized minerals and encapsulated nutrients. They represent a cutting-edge approach to fertilizer efficiency.

Conclusion

Understanding the raw materials for making fertilizers is fundamental for advancing agricultural productivity and sustainability. From traditional sources like ammonia and phosphate rock to innovative materials like biofertilizers and nanomaterials, the spectrum of raw materials is vast and continually expanding. As we address environmental challenges and resource limitations, focusing on efficient and responsible use of these materials is imperative. Embracing advancements in granular fertilizer production can lead to more sustainable agricultural practices, ensuring food security for future generations.

Frequently Asked Questions

Q1: What are the primary raw materials used in nitrogen fertilizer production?

A1: The primary raw materials for nitrogen fertilizers are ammonia, derived from atmospheric nitrogen and hydrogen from natural gas, and urea, produced by combining ammonia and carbon dioxide.

Q2: How does granulation benefit fertilizer application?

A2: Granulation enhances the physical properties of fertilizers, improving handling, storage, and uniform nutrient distribution in the soil, which is essential in granular fertilizer production.

Q3: Why is phosphate rock important in fertilizer manufacturing?

A3: Phosphate rock is the primary source of phosphorus in fertilizers. Processing it yields phosphoric acid, which is essential for producing various phosphorus-based fertilizers vital for plant energy transfer and genetic material formation.

Q4: What environmental concerns are associated with fertilizer raw materials?

A4: Environmental concerns include resource depletion of finite raw materials like phosphate rock, high energy consumption and greenhouse gas emissions during production, and pollution from nutrient runoff leading to water eutrophication.

Q5: How do biofertilizers differ from traditional fertilizers?

A5: Biofertilizers use living microorganisms to enhance nutrient availability, unlike traditional fertilizers that supply nutrients directly. They promote eco-friendly agriculture by improving soil health and reducing chemical fertilizer dependence.

Q6: What role do micronutrients play in plant growth?

A6: Micronutrients, though required in small amounts, are crucial for various physiological functions in plants, including enzyme activation, chlorophyll synthesis, and disease resistance. Deficiencies can significantly impact crop yield and quality.

Q7: Can organic raw materials fully replace synthetic fertilizers?

A7: Organic raw materials like manure and compost improve soil health and provide nutrients but may not meet all the nutrient demands of high-yielding crops. A balanced approach combining organic and synthetic fertilizers often yields the best results.